![The Valentine’s Day Supply Chain [Infographic]](https://www.fronetics.com/wp-content/uploads/2024/10/Valentines-Day-Supply-Chain1-800x675.jpg)

by Fronetics | Feb 3, 2015 | Blog, Strategy, Supply Chain

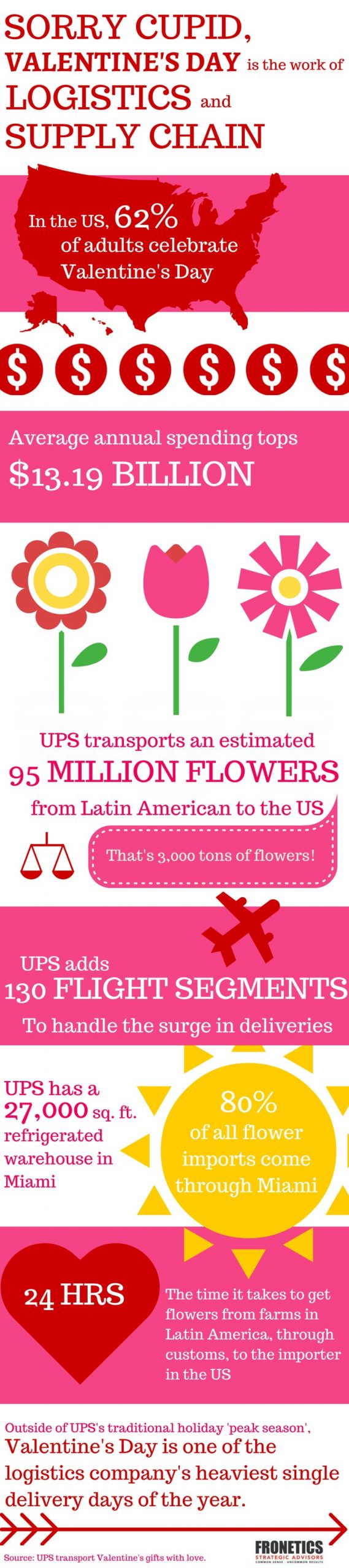

The Valentine’s Day supply chain by the numbers.

In the late 400s Gelasius declared February 14th as a day for honoring Saint Valentine. Over the years February 14th became associated with love and romance (1300s) and the exchange of cards (1600s). In the 1840s the first mass produced Valentine’s Day cards were sold in the US.

Over the years Valentine’s Day has become big business. 62% of adults in the US say that they celebrate the holiday. Spending for Valentine’s Day tops $13.9 billion. $8.9 billion is spent on sparkling wine (174,000 gallons are sold during the holiday week alone). The number of cards and gifts exchanged totals 150 million.

Cupid gets the credit for the holiday, but really Valentine’s Day is the work of logistics and supply chain. UPS alone transports more than 3,000 tons of flowers for Valentine’s Day – requiring the company to add an additional 130 flight segments.

Check out our infographic. You’ll see that Cupid really doesn’t play much of a role (sorry Cupid).

![The Valentine’s Day Supply Chain [Infographic]](https://www.fronetics.com/wp-content/uploads/2024/10/Valentines-Day-Supply-Chain1-800x675.jpg)

by Fronetics | Feb 3, 2015 | Blog, Strategy, Supply Chain

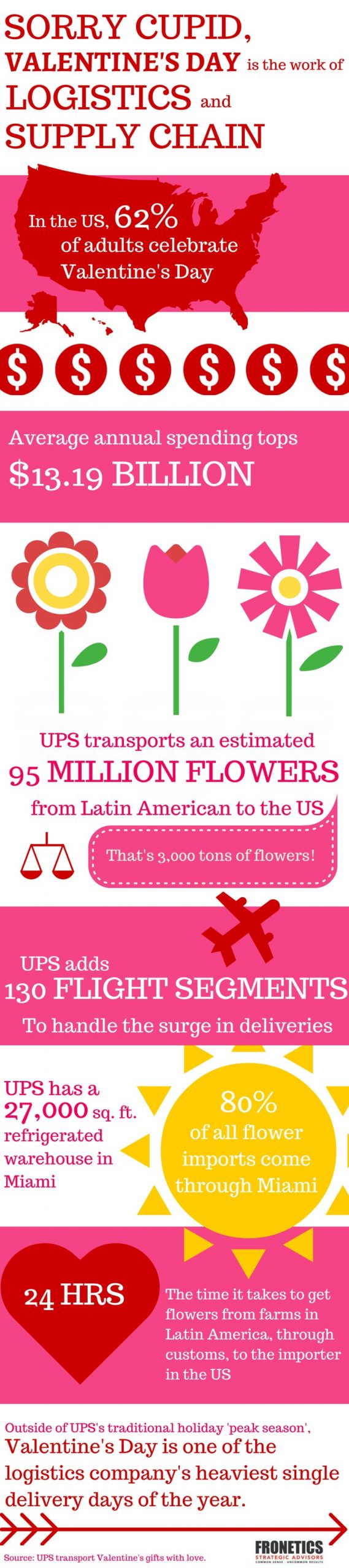

The Valentine’s Day supply chain by the numbers.

In the late 400s Gelasius declared February 14th as a day for honoring Saint Valentine. Over the years February 14th became associated with love and romance (1300s) and the exchange of cards (1600s). In the 1840s the first mass produced Valentine’s Day cards were sold in the US.

Over the years Valentine’s Day has become big business. 62% of adults in the US say that they celebrate the holiday. Spending for Valentine’s Day tops $13.9 billion. $8.9 billion is spent on sparkling wine (174,000 gallons are sold during the holiday week alone). The number of cards and gifts exchanged totals 150 million.

Cupid gets the credit for the holiday, but really Valentine’s Day is the work of logistics and supply chain. UPS alone transports more than 3,000 tons of flowers for Valentine’s Day – requiring the company to add an additional 130 flight segments.

Check out our infographic. You’ll see that Cupid really doesn’t play much of a role (sorry Cupid).

by Fronetics | Feb 2, 2015 | Blog, Supply Chain

Outsourcing fulfillment can makes sense.

Amazon has set the standard for speedy fulfillment.

Despite being both parodied (make sure to watch Netflix’s Drone to Home video) and parroted (the FAA recently clipped a brewery’s attempt to deliver beer by drone to Minnesota fishermen), Amazon insists unmanned aerial delivery vehicles will soon be as common as mail trucks.

While we wait for products to drop from the sky, outsourcing fulfillment to the right provider has never been more important for businesses vying for attention from consumers used to free two-day and next-day deliveries.

“The reality is that Amazon is so big that they are now mandating what the customer satisfaction requirements are for everyone, even if you don’t think that you compete with Amazon,” Jim Tompkins, president of Tompkins International, once told Modern Materials Handling.

If you are dealing with the following issues, you may want to take a good look at fulfillment business partners:

- You are spending a disproportionate amount of time and money on filling orders.

- The size of your warehouse is keeping your company from growing.

- You would rather spend your expertise on developing and marketing your products.

- The cost of warehouse equipment and warehouse employees is too high.

Also, keep in mind:

- Fulfillment cost: As a first step, make sure you know your exact fulfillment cost per order before you start gathering quotes from fulfillment companies.

- Proximity: Your fulfillment should be located as close to your customers as possible, not only to reduce shipping costs but also to achieve that necessary speed of delivery. Once again, Amazon has taken the lead by investing untold amounts in building distribution centers within 200 miles of major metropolitan areas.

- Scalability: Scalability is important, as well. Can the third-party distribution center grow with your business and absorb the seasonal peaks and valleys of ordering?

And finally, be diligent about researching your chosen provider. Ask targeted questions such as:

- Is the fulfillment center financially sound? Inquire about debt and ask for bank references.

- What is its reputation? Check how long the company has been in business and its credibility in the industry.

- What kind of technology does it use? The systems in place will tell you about the service that you can expect.

- How effectively does it communicate? Great communication is key when dealing with back orders, returned items, and cancellations.

Companies that cannot match Amazon’s speed of delivery run the risk of making a quick exit.

by Fronetics | Feb 2, 2015 | Blog, Supply Chain

Outsourcing fulfillment can makes sense.

Amazon has set the standard for speedy fulfillment.

Despite being both parodied (make sure to watch Netflix’s Drone to Home video) and parroted (the FAA recently clipped a brewery’s attempt to deliver beer by drone to Minnesota fishermen), Amazon insists unmanned aerial delivery vehicles will soon be as common as mail trucks.

While we wait for products to drop from the sky, outsourcing fulfillment to the right provider has never been more important for businesses vying for attention from consumers used to free two-day and next-day deliveries.

“The reality is that Amazon is so big that they are now mandating what the customer satisfaction requirements are for everyone, even if you don’t think that you compete with Amazon,” Jim Tompkins, president of Tompkins International, once told Modern Materials Handling.

If you are dealing with the following issues, you may want to take a good look at fulfillment business partners:

- You are spending a disproportionate amount of time and money on filling orders.

- The size of your warehouse is keeping your company from growing.

- You would rather spend your expertise on developing and marketing your products.

- The cost of warehouse equipment and warehouse employees is too high.

Also, keep in mind:

- Fulfillment cost: As a first step, make sure you know your exact fulfillment cost per order before you start gathering quotes from fulfillment companies.

- Proximity: Your fulfillment should be located as close to your customers as possible, not only to reduce shipping costs but also to achieve that necessary speed of delivery. Once again, Amazon has taken the lead by investing untold amounts in building distribution centers within 200 miles of major metropolitan areas.

- Scalability: Scalability is important, as well. Can the third-party distribution center grow with your business and absorb the seasonal peaks and valleys of ordering?

And finally, be diligent about researching your chosen provider. Ask targeted questions such as:

- Is the fulfillment center financially sound? Inquire about debt and ask for bank references.

- What is its reputation? Check how long the company has been in business and its credibility in the industry.

- What kind of technology does it use? The systems in place will tell you about the service that you can expect.

- How effectively does it communicate? Great communication is key when dealing with back orders, returned items, and cancellations.

Companies that cannot match Amazon’s speed of delivery run the risk of making a quick exit.

by Fronetics | Jan 29, 2015 | Blog, Supply Chain, Talent

Millennials are Poised to Change the Supply Chain Industry

This is part two in a two-part series examining the role of Millennials in the supply chain industry. Part one highlights strategies for attracting and retaining top Millennial talent.

With supply chain industry leaders lamenting a growing talent gap, tapping the Millennial generation may be key to filling that gap. But how, exactly? A closer look at the generational characteristics emerging from the influence of digital technology and pervasive interconnectedness allows us to draw inferences about the potential Millennial contributions to the supply chain industry.

Here are four areas where Millennials are poised to change the supply chain industry.

Internet of Things (IoT)

The Internet of Things (IoT), loosely defined as the growing and pervasive use of interconnected devices, is rising concurrently with Millennials entering the workforce. Born and raised during the digital revolution, they’re accustomed to products and processes that are highly integrated and interconnected. Supply chain companies should tap Millennials to leverage their unique perspective by engaging them in creative and strategic thinking about optimizing operational processes using interconnected devices, sensors, and tracking tools and soliciting ideas to grow revenue through the production of devices.

Marketing and Sales Approaches

Targeted for advertisements from an earlier age than their parents and grandparents, Millennials have been desensitized to overt branding messages. Instead, they respond to more organic marketing and sales approaches – strategies that can be expected to carry over into their work. Further, following current trends that deploy digital and social media, Millennials will seek to shift sales and marketing activities online to develop more meaningful, solutions-based relationships with buyers.

Global Partnerships

Ubiquitous and immediate virtual access to resources, information, networks, and people make Millennials the most interconnected generation. That unencumbered access, coupled with a tendency to favor collaborative decision-making in their work, creates opportunities for global work spaces and more complex industry partnerships – particularly relevant and significant advantages to companies within the supply chain industry.

Big Data

Similar to the way Millennials relate to the Internet of Things, so too will big data emerge as a tool Millennials will use to transform the supply chain industry. Their digital confidence and understanding of the types of information and data being collected and analyzed by companies will lead to gains in supply chain operational efficiency as Millennials seek to analyze robust data and apply their findings in practical ways.

With Millennials positioned to outnumber Baby Boomers in the workplace by 2020, shifts in ideas and processes are inevitable. What other supply chain elements do you see as ripe for transformation by Millennials?

![The Valentine’s Day Supply Chain [Infographic]](https://www.fronetics.com/wp-content/uploads/2024/10/Valentines-Day-Supply-Chain1-800x675.jpg)