by Fronetics | Mar 23, 2015 | Blog, Supply Chain, Talent

What you need to know about the supply chain talent gap.

The supply chain talent gap has been called a “perfect storm.” Few topics are shrouded in such doom and gloom. Every report cites doomsday statistics of the impending crisis when, by 2025, 60 million baby boomers will exit the workforce, leaving a gigantic gap when 40 million millennials take their place. To make matters worse, the retirement exodus is only one factor contributing to the sinking ship. Future supply chain professionals need to master not only the hard analytical skills but also the soft leadership skills fueled by the transition from an industrial economy to an economy grounded in service and information. In numbers, it means only 20% of the workforce will possess the skills required of 60% of all new supply chain jobs.

But listen up, all you forward-thinking millennials and midlevel supply chain managers with cross-functional expertise. There’s some good news: The market can’t get enough of you.

Yes, amid all the dire facts, there is opportunity. There has never been a better time to be, so to speak, on the other side of the table — a college graduate or a motivated professional looking for a career with upward mobility? What other field of work can offer as much promise to new recruits and current employees as the supply chain industry?

Just as all reports predict a brewing crisis, they also tout talent management as the primary remedy. For a self-motivated individual, fresh out of college or in the midst of a corporate climb, this focus on professional development presents a smorgasbord of options. Many companies have taken note and adopted a strategy of action for recruiting and retaining new talent. A growing number of university program offerings reflect a strengthening partnership between academia and the supply chain industry. Many supply chain companies are building partnerships with academic programs to offer internship opportunities; a move that’s creating strong early relationships with students and will likely have a positive effect on future recruitment efforts. A company that can offer its current staff competitive salaries in addition to cross-functional training is much better positioned to meet the challenges of the talent shortage and the evolving nature and demands of the supply chain.

Another way companies within the logistics and supply chain industries are attracting top talent is through their use of social media. Considering the global reach and vast talent pool of LinkedIn’s 300 million users, the business-focused social network is helping companies with open positions that might require a unique and specific skill set to connect with candidates across the globe.

What’s clear is that companies that follow a plan of inaction will be left behind. This new talent pool will swiftly turn down a company that remains stuck on strict functional divisions and favors the old siloed approach to doing business. Many supply chain managers have grown up in such divided organizations themselves, so they have been slow to take appropriate action to retain and train talent, according to a Supply Chain Insights survey, leaving those better prepared with a competitive advantage.

If a company does not appeal to the desires of top candidates, individuals will take their talent elsewhere. And there will always be another company to welcome them. As Rebooting Work author Maynard Webb points out in a 2013 interview with Elance, in order for companies to remain competitive they’ll need to adapt to the modern workforce. “Companies have traditionally thought of people as a disposable resource,” he says. “They have valued their buildings much more than employees… this doesn’t make sense in a world where the best people can choose to work wherever they want. Businesses have to realize that some jobs can be done from anywhere, anytime, and save the brick and mortar buildings for the few jobs that demand a physical presence.”

Touting the unlimited opportunities and unparalleled growth in the supply chain field should be part of turning the tide. Sure, there is a lot of talk about doom, but mainly for those companies that fail to attract and retain top talent.

by Fronetics | Mar 9, 2015 | Blog, Supply Chain

The Internet of Things (IoT) “represents the convergence of the physical and digital worlds. Physical objects are equipped with technology that enables the object to send and receive information via fixed-wire or wireless communications links to the Internet, and to then transmit information in one form or another.”

In 2003 there were an estimated 500 million IoT-connected devices. By 2010 there were 12.5 billion connected devices. Morgan Stanley estimates that there will be 75 billion IoT devices by 2020. Cisco makes a more conservative estimate 50 billion. Whether it is Morgan Stanley or Cisco who proves correct, what is clear is that the number of internet connected devices is growing exponentially.

Consumer convenience is often the focus of the IoT. However, the capabilities of the IoT reach far beyond consumer convenience. The IoT is game-changing for the logistics and supply chain industries. The IoT delivers the visibility and data necessary for supply chain optimization.

One Network Enterprises, a supply chain technology provider, offers this supply chain example:

“[The IoT] refers to data communication among a large range of assets or devices—from your fridge to your oven or, more pertinently, from your inventory to its container, from the container to the carrier, from the pallet to the warehouse. The more your assets can ‘speak’ to one another and share data, the more they can work together to help you improve your processes.”

The IoT has already moved into industrial environments including warehouses and manufacturing plants.

Examples of where the IoT is already having an impact on supply chains include:

- Transparency and visibility

- Proactive replenishment

- Predictive maintenance

- Reduction in asset loss

- Manufacturing flow management

- Product development and commercialization.

- Risk management.

- Operational efficiency

- Improved fleet management

The transparency and end-to-end visibility afforded by the IoT creates new opportunities that supply chain professionals can leverage in order to optimize supply chains and generate value. It is important to look at the potential of the IoT now and not later. The amount of data alone that is generated by the IoT creates a paradigm shift. Companies that embrace the Internet of Things and identify where and how it can play a role for their business will move forward and leave those who do not behind.

The Internet of Things has the potential to change everything.

To learn more about how the Internet of Things has and will continue to impact the supply chain see the full article How the Internet of Things will change your world on Supply Chain Quarterly. The article includes a focus on Internet of things and the warehouse.

by Fronetics | Mar 9, 2015 | Blog, Supply Chain

The Internet of Things (IoT) “represents the convergence of the physical and digital worlds. Physical objects are equipped with technology that enables the object to send and receive information via fixed-wire or wireless communications links to the Internet, and to then transmit information in one form or another.”

In 2003 there were an estimated 500 million IoT-connected devices. By 2010 there were 12.5 billion connected devices. Morgan Stanley estimates that there will be 75 billion IoT devices by 2020. Cisco makes a more conservative estimate 50 billion. Whether it is Morgan Stanley or Cisco who proves correct, what is clear is that the number of internet connected devices is growing exponentially.

Consumer convenience is often the focus of the IoT. However, the capabilities of the IoT reach far beyond consumer convenience. The IoT is game-changing for the logistics and supply chain industries. The IoT delivers the visibility and data necessary for supply chain optimization.

One Network Enterprises, a supply chain technology provider, offers this supply chain example:

“[The IoT] refers to data communication among a large range of assets or devices—from your fridge to your oven or, more pertinently, from your inventory to its container, from the container to the carrier, from the pallet to the warehouse. The more your assets can ‘speak’ to one another and share data, the more they can work together to help you improve your processes.”

The IoT has already moved into industrial environments including warehouses and manufacturing plants.

Examples of where the IoT is already having an impact on supply chains include:

- Transparency and visibility

- Proactive replenishment

- Predictive maintenance

- Reduction in asset loss

- Manufacturing flow management

- Product development and commercialization.

- Risk management.

- Operational efficiency

- Improved fleet management

The transparency and end-to-end visibility afforded by the IoT creates new opportunities that supply chain professionals can leverage in order to optimize supply chains and generate value. It is important to look at the potential of the IoT now and not later. The amount of data alone that is generated by the IoT creates a paradigm shift. Companies that embrace the Internet of Things and identify where and how it can play a role for their business will move forward and leave those who do not behind.

The Internet of Things has the potential to change everything.

To learn more about how the Internet of Things has and will continue to impact the supply chain see the full article How the Internet of Things will change your world on Supply Chain Quarterly. The article includes a focus on Internet of things and the warehouse.

by Fronetics | Feb 19, 2015 | Blog, Strategy, Supply Chain, Warehousing & Materials Handling

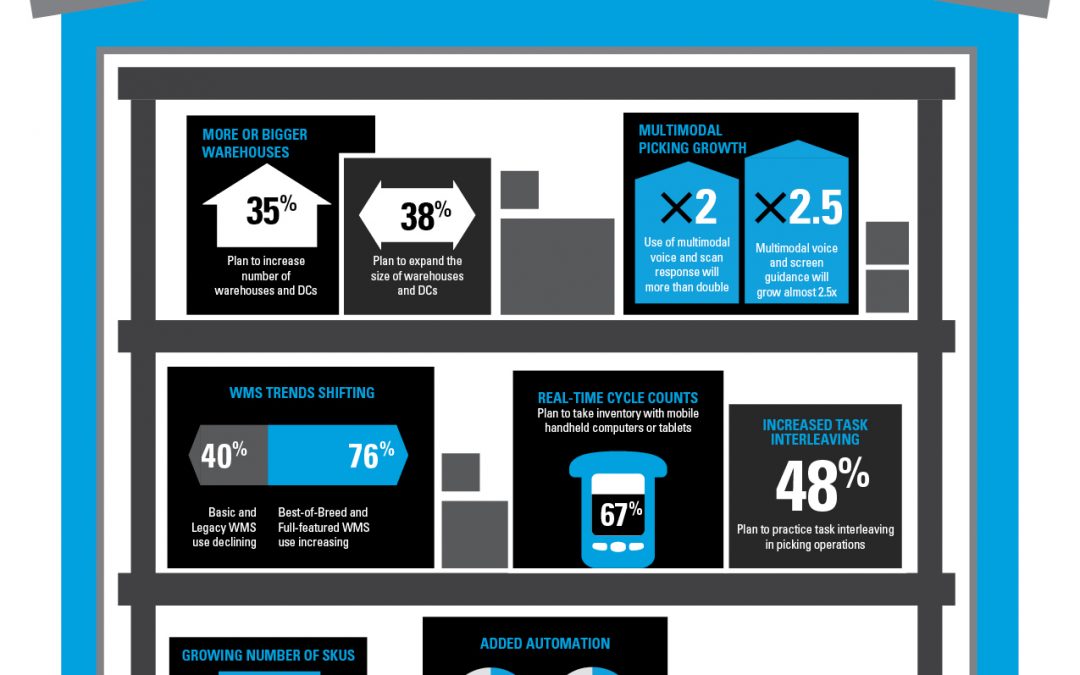

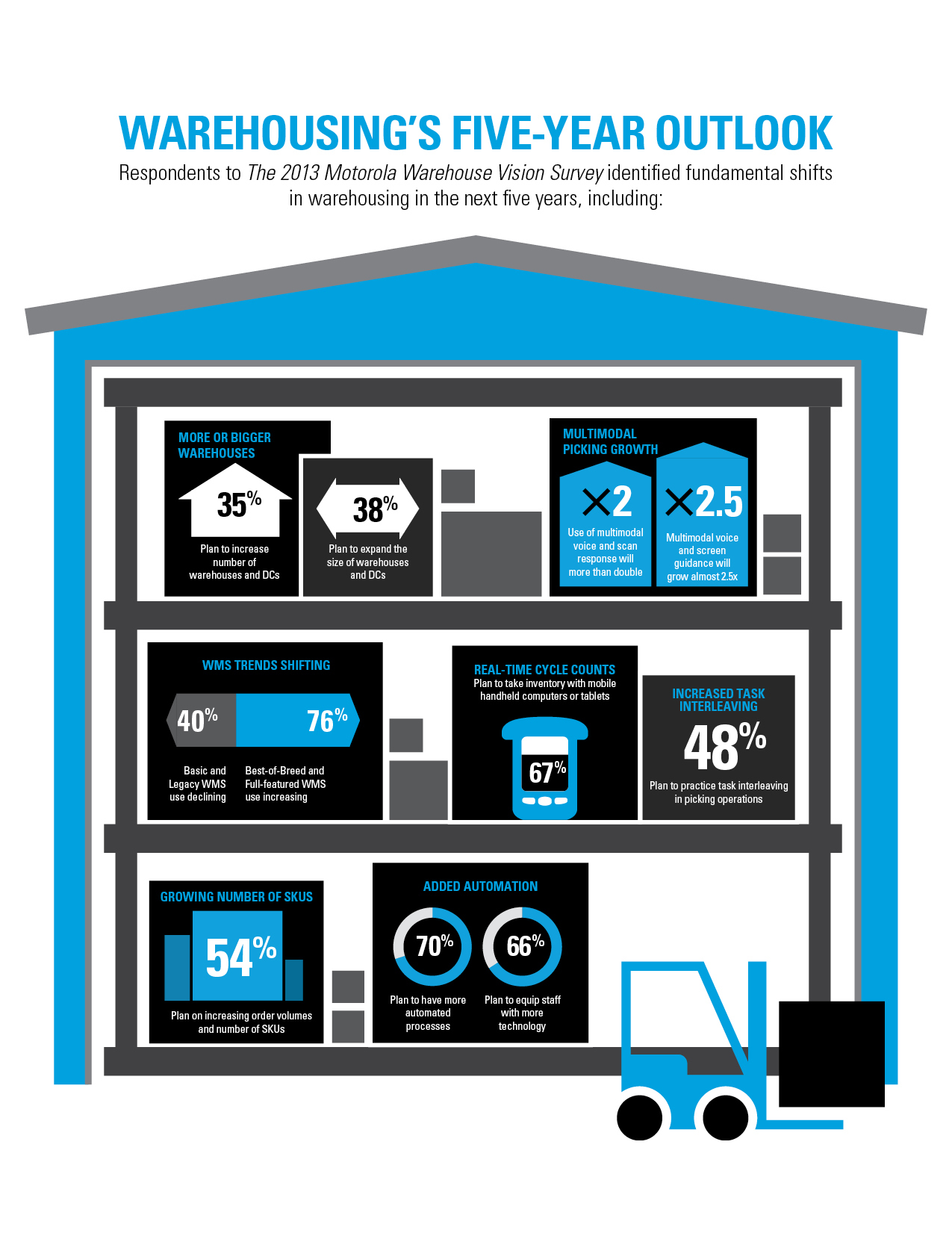

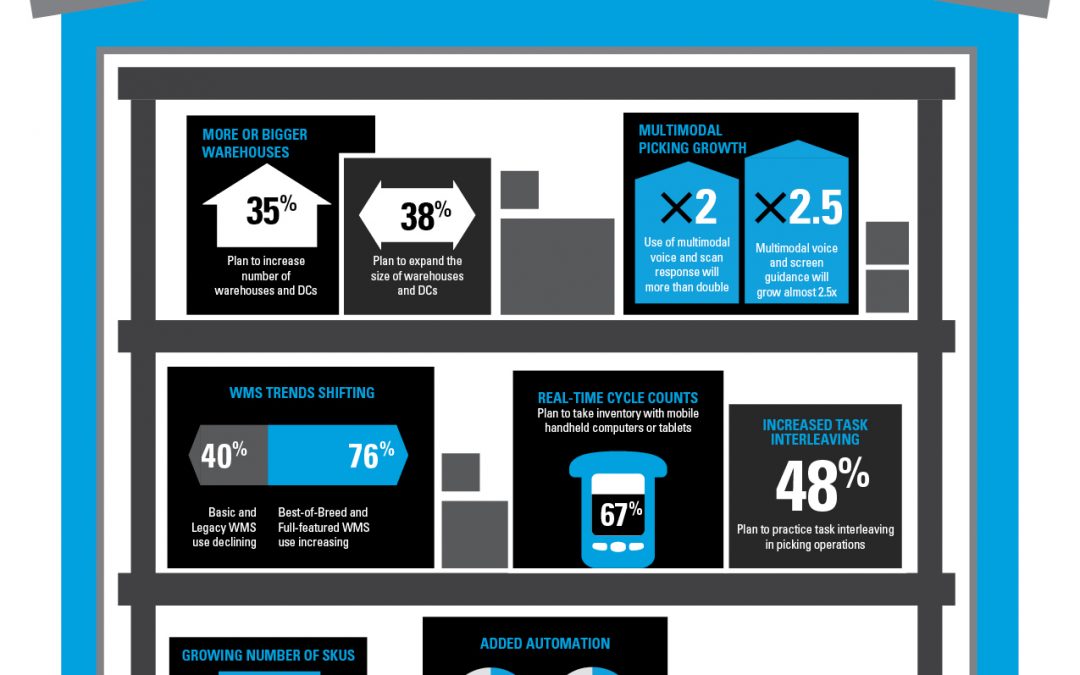

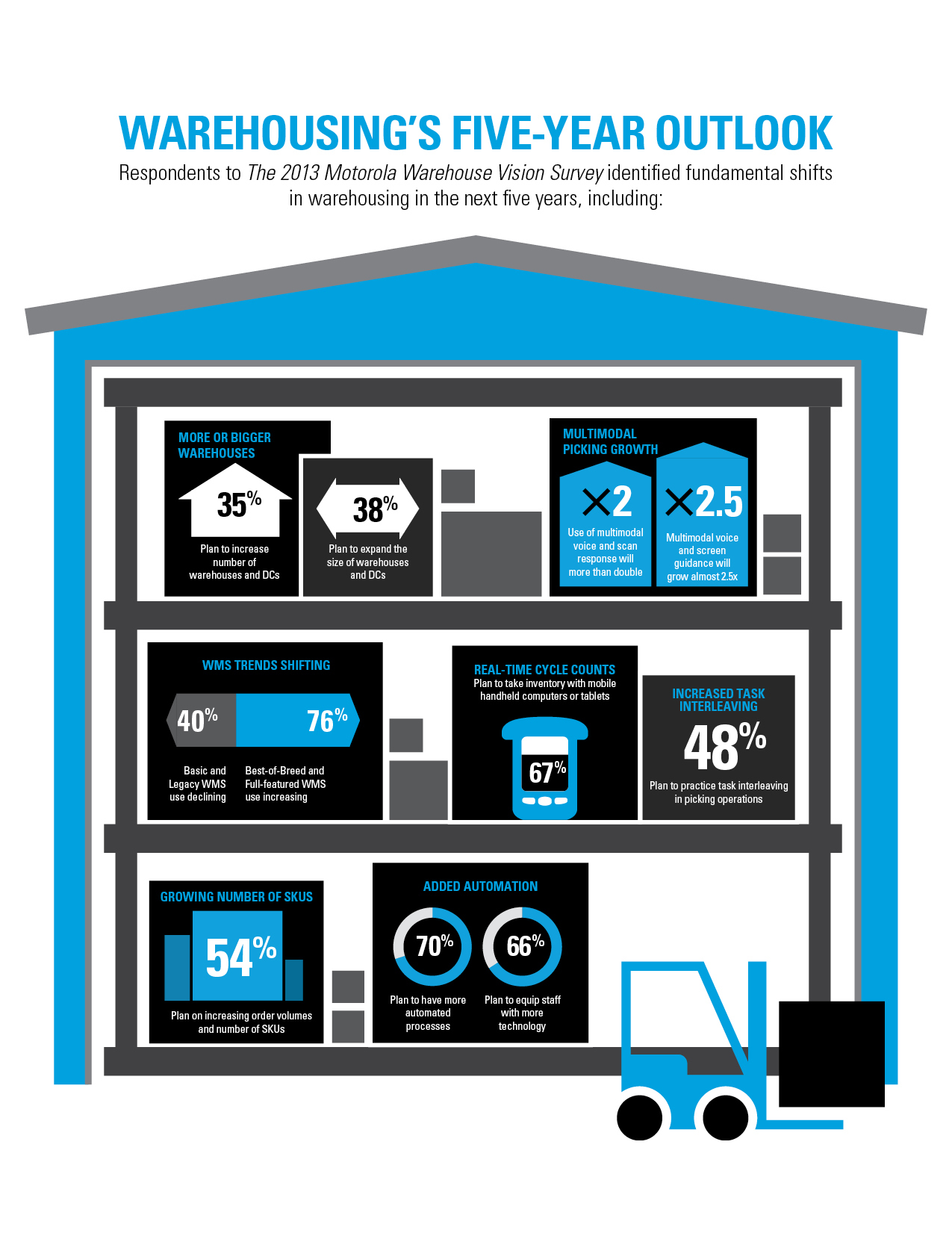

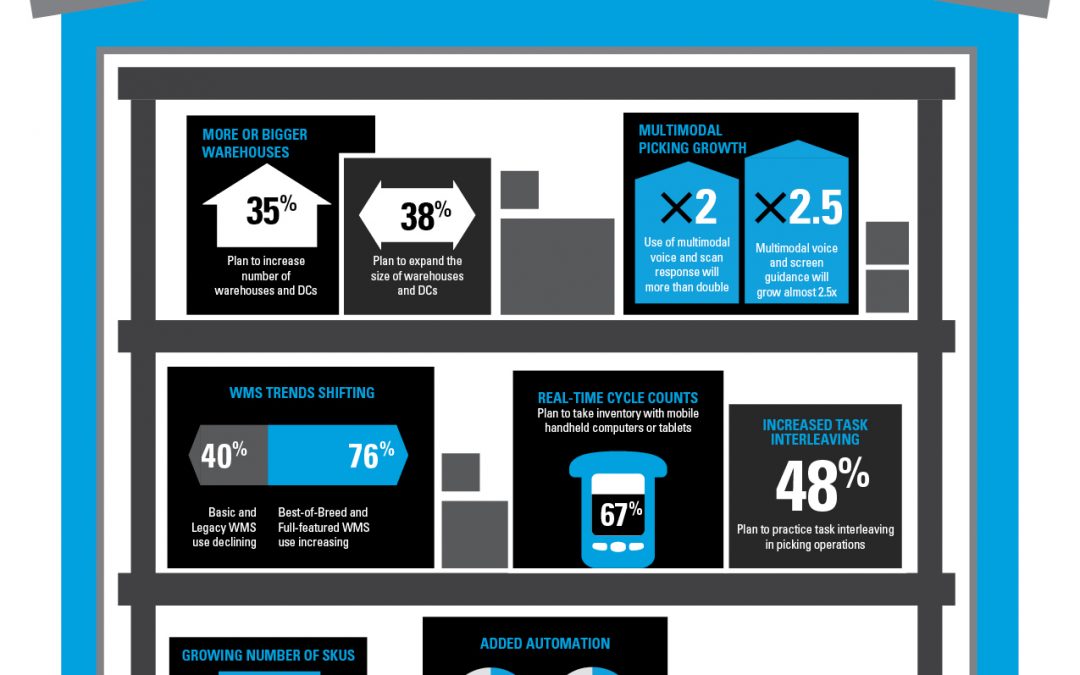

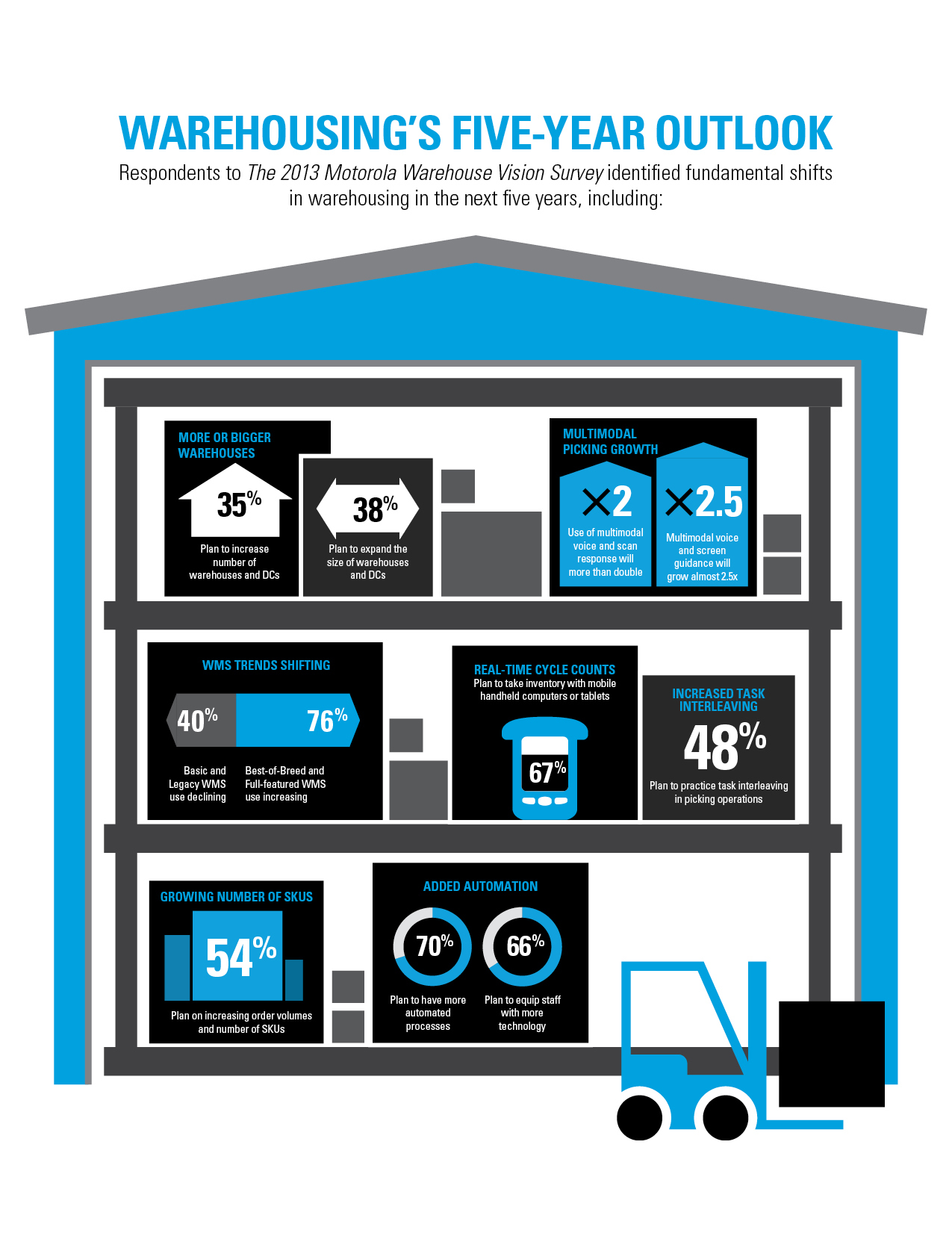

Source: Motorola

Growing in concert with consumer demand, distribution centers are getting bigger. In fact, a 2013 Motorola Warehouse Vision Survey reported that a full thirty-eight percent of respondents would be increasing the size of their warehouses and distribution centers over the next five years. And while there are certainly potential benefits, there are also plenty of potential problems. With good planning, though, organizations can successfully navigate around the pitfalls of distribution center growth.

Here’s how to achieve success when growing the size of your distribution center.

Streamline operations and processes

Increasing the square footage of your distribution center requires extensive strategy pre-planning. This means taking stock of your entire logistics and distribution process and strategically thinking about how these processes can be made more efficient. Areas where many companies can increase efficiencies include: decreasing reliance on paper, cross-docking, incorporating multi-modal wireless solutions, and revamping the pick strategy.

Optimize communication across departments

Communication is essential when growing your distribution center. Communicating across departments will enable your company to be able to effectively plan for both current capacity requirements as well as capacity requirements that are forecasted in the near-, mid-, and long-term. Building a larger distribution center only to outgrow it five years later is a costly mistake. Furthermore, communication across departments will allow for the right-sizing of both equipment and labor.

Be flexible

Allowing for flexibility is a key factor of successful growth. A large distribution center that can process a limited number of SKUs is, well, limited. A distribution center that is designed to be able to process a wide variety of goods and SKUs can reduce operating costs and enable your company to be more nimble. When designing your distribution center, keep flexibility at the forefront.

Invest and utilize technology

A larger distribution center requires more automation and more technology than a smaller distribution center. Similarly, a larger distribution benefits from mobile solutions. As more specific and sophisticated technology emerges, implementing smart technologies can aid in your efforts to achieve optimization of communications and streamline your operations more efficiently.

When the square footage of your distribution center grows, it is important to remember that you are dealing with a different beast. It’s one that requires extra careful thought. Taking the time to consider potential problems and preparing a solid plan of implementation before you begin will increase your odds of successful growth.

by Fronetics | Feb 19, 2015 | Blog, Strategy, Supply Chain, Warehousing & Materials Handling

Source: Motorola

Growing in concert with consumer demand, distribution centers are getting bigger. In fact, a 2013 Motorola Warehouse Vision Survey reported that a full thirty-eight percent of respondents would be increasing the size of their warehouses and distribution centers over the next five years. And while there are certainly potential benefits, there are also plenty of potential problems. With good planning, though, organizations can successfully navigate around the pitfalls of distribution center growth.

Here’s how to achieve success when growing the size of your distribution center.

Streamline operations and processes

Increasing the square footage of your distribution center requires extensive strategy pre-planning. This means taking stock of your entire logistics and distribution process and strategically thinking about how these processes can be made more efficient. Areas where many companies can increase efficiencies include: decreasing reliance on paper, cross-docking, incorporating multi-modal wireless solutions, and revamping the pick strategy.

Optimize communication across departments

Communication is essential when growing your distribution center. Communicating across departments will enable your company to be able to effectively plan for both current capacity requirements as well as capacity requirements that are forecasted in the near-, mid-, and long-term. Building a larger distribution center only to outgrow it five years later is a costly mistake. Furthermore, communication across departments will allow for the right-sizing of both equipment and labor.

Be flexible

Allowing for flexibility is a key factor of successful growth. A large distribution center that can process a limited number of SKUs is, well, limited. A distribution center that is designed to be able to process a wide variety of goods and SKUs can reduce operating costs and enable your company to be more nimble. When designing your distribution center, keep flexibility at the forefront.

Invest and utilize technology

A larger distribution center requires more automation and more technology than a smaller distribution center. Similarly, a larger distribution benefits from mobile solutions. As more specific and sophisticated technology emerges, implementing smart technologies can aid in your efforts to achieve optimization of communications and streamline your operations more efficiently.

When the square footage of your distribution center grows, it is important to remember that you are dealing with a different beast. It’s one that requires extra careful thought. Taking the time to consider potential problems and preparing a solid plan of implementation before you begin will increase your odds of successful growth.