by Fronetics | Apr 7, 2015 | Blog, Leadership, Strategy

There are times when change is good. There are also times when change is bad for business.

The phrase “If it ain’t broke, don’t fix it” is often attributed to Thomas Bertram Lance, businessman and Director of the Office of Management and Budget under President Jimmy Carter. He was quoted in the May 1977 issue of the magazine Nation’s Business, though the sentiment feels as old as human existence. If something is working, and has always worked, then why change it? There are many adages along the same lines: leave well enough alone, never change a running system, don’t change a winning team.

True, humans are always evolving, but we also like consistency and stability. In his book Handbook of Contemporary Economics, Morris Altman wrote, “Without some stability over at least the short term, it is hard to conceive of humans engaging in sustained goal-oriented activity.” Change, adaptability, and flexibility, especially in business culture and lore, have turned from buzzwords to commandments. There are some things, though, that don’t require change. Assess whether change is necessary, rather than assuming it is because it’s socially and commercially popular. Ask:

- Are there assessment tools in place to monitor the business’s success?

- Are customers reporting satisfaction?

- Do your goods match customer needs?

- Do you understand the current market and your place amongst competitors?

- Are profits growing?

- Are overall finances sound?

- Are things running efficiently?

- Are current practices meeting regulations?

- Do you have the right people to meet your objectives?

- Are employees engaged, trained, and developing?

If the answer to these questions is yes, then why change? According to Harvard Business Review change could alienate your base, confuse people, damage your brand, and lose you money. Cadbury and its parent company, Kraft, are experiencing intense backlash due to a change in the Cadbury Creme Egg recipe. People are protesting, writing letters, posting negative comments online, and accusing the company of “ruining Easter.” We’ve seen this before. According to TIME’s article on the top 10 bad beverage ideas, “April 23, 1985, stands as one of the most significant dates in business history — the date the 99-year-old Coca-Cola company announced it was scrapping its original soda formula for a newer, sweeter version.” This change brought with it over 40,000 letters of protest, not to mention the bad press. Within three months the original soda formula, Coca-Cola “classic”, was back and met with an incredibly positive reception.

Some companies opt for a subtler approach to change by expanding its traditional offering. Instead of changing the successful product line for women, Dove expanded into the male market, creating Dove Men+Care, while still adhering to their public image and mission of creating personal care products that support natural health and realistic beauty.

The Harvard Business Review lists Brooks Brothers as a company that successfully found new opportunities without changing its values, “Instead of simply sticking to selling classic clothing, and waiting for outside catalysts (such as the popularity of the fashion in the television show Mad Men) to increase its popularity, the chain innovated around the edges by offering more fashionable accessories — shoes, belts, bags and the like — while leaving its core basically unchanged.” Capitalizing on this opportunity did not drive customers away because Brooks Brothers’ base products remained.

Remember that change has a cost. Are your consumers willing to pay the cost, especially if they didn’t require the change in the first place? Will your partners in the supply chain be willing to do business with you if the change you implement doesn’t suit them or benefit them? Think about some of the elements, for example, of a brand change:

- Content

- Communication

- Collateral

- Contacts

Things such as graphic design, business cards, letterhead, social media, advertising, re-launch, etc. all require real time and money. You must assess if your change will reap real, solid benefits. You don’t want to expend the effort, time, and money to change if you don’t have to, especially if it requires reversing the change or worse, killing your business.

by Elizabeth Hines | Apr 6, 2015 | Big Data, Blog, Data/Analytics

Concurrent with the extraordinary rise of the Internet of Things (IoT), predictive analytics are gaining in popularity. With an increasing number of companies learning to master the precursors to developing predictive models — namely, connecting, monitoring, and analyzing — we can safely assume the art of gleaning business intelligence from foresight will continue to grow rapidly.

Indeed, Gartner analysts put forward that “few technology areas will have greater potential to improve the financial performance and position of a commercial global enterprise than predictive analytics.” And executives seem eager to jump on the bandwagon; in a survey of executives conducted by Accenture a full 88% indicated big data analytics is a top priority for their company. Amid the promises of predictive analytics, however, we also find a number of pitfalls. Some experts caution there are situations when predictive analytics techniques can prove inadequate, if not useless.

Here, we dissect three problems most commonly encountered by companies employing predictive analytics.

Past as a poor predictor of the future

The concept of predictive analytics is predicated on the assumption that future behavior can be more or less determined by examining past behaviors; that is, predictive analytics works well in a stable environment in which the future of the business is likely to resemble its past and present. But Harvard Business School professor Clayton Christensen points out that in the event of a major disruption, the past will do a poor job of foreshadowing future events. As an example, he cites the advent of PCs and commodity servers, arguing computer vendors who specialized in minicomputers in the 1980s couldn’t possibly have predicted their sales impact, since they were innovations and there was no data to analyze.

Interpreting bias

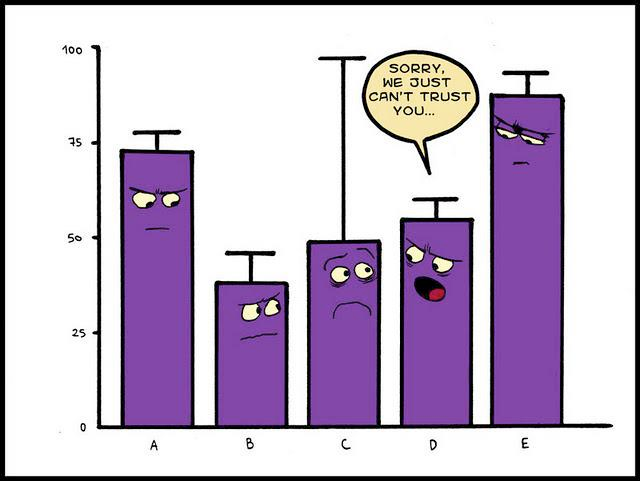

Consider also the bias in favor of a positive result when interpreting data for predictive purposes; it is one of the most common errors in predictive analytics projects. Speaking at the 2014 Predictive Analytics World conference in Boston, John Elder, president of consulting firm Elder Research, Inc., made a good point when he noted that people “‘often look for data to justify our decisions,’ when it should be the other way around.”

Collecting and analyzing unhelpful or superfluous data

Failure to tie data efforts to operational processes can lead to an unnecessary drain of staff resources. Mining big data will do little good if the insights are not directly tied to functional procedures. More companies than we probably realize are wasting precious time and manpower on big data projects that are not adequately understood, producing trivia rather than actionable business intelligence.

To overcome these common pitfalls of predictive analytics, spend some time reviewing the sources of your data and the basic assumptions on which your predictive analytics projects are based. Because the major principle of predictive analytics is that the past behavior can forecast future behavior, keep your ear to the ground for growing industry trends or any other factors that might influence consumer behavior. Plan to revisit the source of your data frequently to determine if the sample set is representative of your future set and should continue to be used. Most importantly, regularly evaluate how your predictive analysis relates and contributes to your company’s overall goals and objectives.

What else do you think organizations can do to ward off the snags of predictive data analysis and use foresight more effectively?

by Elizabeth Hines | Apr 6, 2015 | Big Data, Blog, Data/Analytics

Concurrent with the extraordinary rise of the Internet of Things (IoT), predictive analytics are gaining in popularity. With an increasing number of companies learning to master the precursors to developing predictive models — namely, connecting, monitoring, and analyzing — we can safely assume the art of gleaning business intelligence from foresight will continue to grow rapidly.

Indeed, Gartner analysts put forward that “few technology areas will have greater potential to improve the financial performance and position of a commercial global enterprise than predictive analytics.” And executives seem eager to jump on the bandwagon; in a survey of executives conducted by Accenture a full 88% indicated big data analytics is a top priority for their company. Amid the promises of predictive analytics, however, we also find a number of pitfalls. Some experts caution there are situations when predictive analytics techniques can prove inadequate, if not useless.

Here, we dissect three problems most commonly encountered by companies employing predictive analytics.

Past as a poor predictor of the future

The concept of predictive analytics is predicated on the assumption that future behavior can be more or less determined by examining past behaviors; that is, predictive analytics works well in a stable environment in which the future of the business is likely to resemble its past and present. But Harvard Business School professor Clayton Christensen points out that in the event of a major disruption, the past will do a poor job of foreshadowing future events. As an example, he cites the advent of PCs and commodity servers, arguing computer vendors who specialized in minicomputers in the 1980s couldn’t possibly have predicted their sales impact, since they were innovations and there was no data to analyze.

Interpreting bias

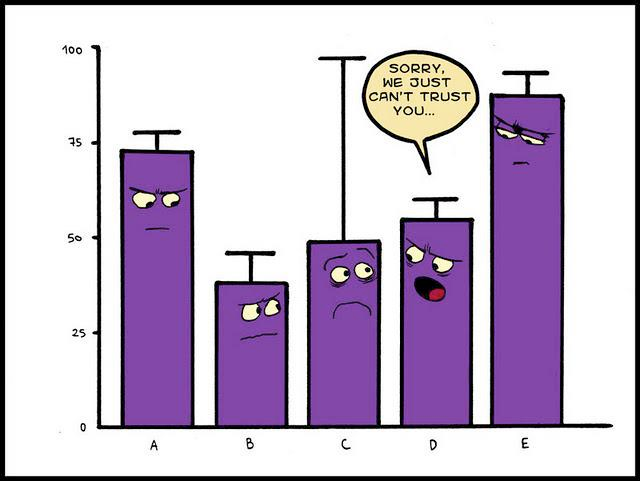

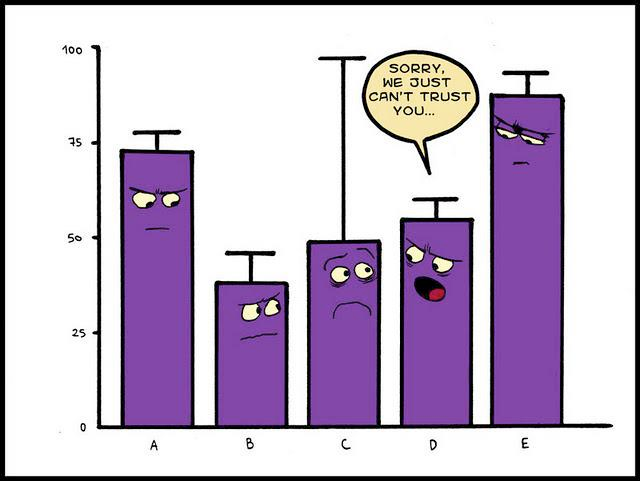

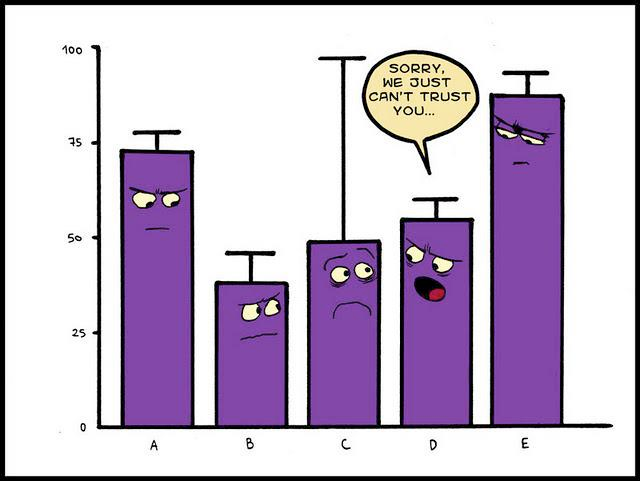

Consider also the bias in favor of a positive result when interpreting data for predictive purposes; it is one of the most common errors in predictive analytics projects. Speaking at the 2014 Predictive Analytics World conference in Boston, John Elder, president of consulting firm Elder Research, Inc., made a good point when he noted that people “‘often look for data to justify our decisions,’ when it should be the other way around.”

Collecting and analyzing unhelpful or superfluous data

Failure to tie data efforts to operational processes can lead to an unnecessary drain of staff resources. Mining big data will do little good if the insights are not directly tied to functional procedures. More companies than we probably realize are wasting precious time and manpower on big data projects that are not adequately understood, producing trivia rather than actionable business intelligence.

To overcome these common pitfalls of predictive analytics, spend some time reviewing the sources of your data and the basic assumptions on which your predictive analytics projects are based. Because the major principle of predictive analytics is that the past behavior can forecast future behavior, keep your ear to the ground for growing industry trends or any other factors that might influence consumer behavior. Plan to revisit the source of your data frequently to determine if the sample set is representative of your future set and should continue to be used. Most importantly, regularly evaluate how your predictive analysis relates and contributes to your company’s overall goals and objectives.

What else do you think organizations can do to ward off the snags of predictive data analysis and use foresight more effectively?

by Fronetics | Apr 1, 2015 | Blog, Internet of Things, Supply Chain

During his TED talk on the Internet of Things (IoT) technologist, Dr. John Barrett, described how every thing: appliances, furniture, vehicles, equipment, soil, food, animals and humans can become connected, identified, monitored, managed, and controlled. By 2032 he predicts that each person could come in contact with 3,000 to 5,000 connected things each day. IBM sees the Internet of Things as the planet’s new central nervous system.

The Internet of Things is already here and developing—monitoring our footsteps, heartbeats, lighting, home temperature and environment— and it will continue to grow at a rapid rate: “The growth in IoT will far exceed that of other connected devices. By 2020, the number of smartphones, tablets, and PCs in use will reach about 7.3 billion units,” said Peter Middleton, research director at Gartner. “In contrast, the IoT will have expanded at a much faster rate, resulting in a population of about 26 billion units at that time.”

The IoT and the Supply Chain

This will have a huge impact on the supply chain as we currently know it. In his talk, Dr. Barrett describes how a food processing company waiting for a delivery of shellfish will be able to not only “know where the food delivery is, but its entire storage and shipping history since the moment it came on board” the boat. Already, some vendors are able to remotely monitor their vending machines and access data about temperature, supply, and theft. In the future vending machines will be able to recognize a customer, recall their past preferences, and “even refuse to vend a certain product based on a shopper’s age, medical record, dietary requirements or purchase history.”

How else will we see IoT inform end-to-end transactions within the supply chain? Transparency in the supply chain is already growing with the swell of ERP and SCM, and with its growth it brings collaboration, clarity, and trust. With the increased use of Radio Frequency Identification (RFID) computer chips can talk to each other, and gather and deliver more detailed information than ever. Visibility in the chain will continue to expand and improve operations. The IoT will impact the supply chain in many ways including the following:

- Stock management

- Preventative maintenance

- User insight

- Manufacturing flow management

- Product stability

- Operational efficiency

- Improved fleet management

An Example of Success

Many companies are already employing the IoT, and as a result they are seeing improvements while working out the kinks of this new technology. UPS has increased single carrier deliveries with the use of sensors. According to David Barnes, the company’s chief information officer, more than 200 measurements can be tracked on a delivery truck from “how fast the vehicle is traveling, how aggressively it’s accelerating or decelerating, the RPMs and the fuel consumption. We can hook into the engine bus environment. We also put in a GPS unit. There are sensors on the engine and on components like starter motors and seat belts.” The analysis of this data is a main focus for UPS and has resulted in improved safety management, fuel efficiency, environmental impact, and customer satisfaction. One carrier reported that his deliveries increased from 90 a day to 120 a day. UPS drivers have seen an increase in salary as the company’s revenue multiplies.

The $1 billion UPS invests in technology per year is producing results, but what are the downfalls of telematics and other advancements? The union representing UPS workers has already set forth some demands: drivers cannot be monitored without being informed and cannot be disciplined “based solely on data.” One driver noted that it “does feel like big brother.”

Issues of security, privacy, accuracy, capacity, and the growth of software substitution in the workplace are all matters that need to be examined as IoT explodes. As IoT matures, it is wise for companies, especially those in manufacturing and logistics, to pay close attention. As reported by Gartner, by 2020, “Economic value-add (which represents the aggregate benefits that businesses derive through the sale and usage of IoT technology) is forecast to be $1.9 trillion across sectors.” With the increased possibility, reach, and data of the IoT will come complex decisions and opportunities for businesses.

Fronetics’ Kate Lee has written extensively about the Internet of Things and the supply chain. Her article, How the Internet of Things will change your world, was published in the Quarter 1, 2015 edition of Supply Chain Quarterly.

by Fronetics | Apr 1, 2015 | Blog, Internet of Things, Supply Chain

During his TED talk on the Internet of Things (IoT) technologist, Dr. John Barrett, described how every thing: appliances, furniture, vehicles, equipment, soil, food, animals and humans can become connected, identified, monitored, managed, and controlled. By 2032 he predicts that each person could come in contact with 3,000 to 5,000 connected things each day. IBM sees the Internet of Things as the planet’s new central nervous system.

The Internet of Things is already here and developing—monitoring our footsteps, heartbeats, lighting, home temperature and environment— and it will continue to grow at a rapid rate: “The growth in IoT will far exceed that of other connected devices. By 2020, the number of smartphones, tablets, and PCs in use will reach about 7.3 billion units,” said Peter Middleton, research director at Gartner. “In contrast, the IoT will have expanded at a much faster rate, resulting in a population of about 26 billion units at that time.”

The IoT and the Supply Chain

This will have a huge impact on the supply chain as we currently know it. In his talk, Dr. Barrett describes how a food processing company waiting for a delivery of shellfish will be able to not only “know where the food delivery is, but its entire storage and shipping history since the moment it came on board” the boat. Already, some vendors are able to remotely monitor their vending machines and access data about temperature, supply, and theft. In the future vending machines will be able to recognize a customer, recall their past preferences, and “even refuse to vend a certain product based on a shopper’s age, medical record, dietary requirements or purchase history.”

How else will we see IoT inform end-to-end transactions within the supply chain? Transparency in the supply chain is already growing with the swell of ERP and SCM, and with its growth it brings collaboration, clarity, and trust. With the increased use of Radio Frequency Identification (RFID) computer chips can talk to each other, and gather and deliver more detailed information than ever. Visibility in the chain will continue to expand and improve operations. The IoT will impact the supply chain in many ways including the following:

- Stock management

- Preventative maintenance

- User insight

- Manufacturing flow management

- Product stability

- Operational efficiency

- Improved fleet management

An Example of Success

Many companies are already employing the IoT, and as a result they are seeing improvements while working out the kinks of this new technology. UPS has increased single carrier deliveries with the use of sensors. According to David Barnes, the company’s chief information officer, more than 200 measurements can be tracked on a delivery truck from “how fast the vehicle is traveling, how aggressively it’s accelerating or decelerating, the RPMs and the fuel consumption. We can hook into the engine bus environment. We also put in a GPS unit. There are sensors on the engine and on components like starter motors and seat belts.” The analysis of this data is a main focus for UPS and has resulted in improved safety management, fuel efficiency, environmental impact, and customer satisfaction. One carrier reported that his deliveries increased from 90 a day to 120 a day. UPS drivers have seen an increase in salary as the company’s revenue multiplies.

The $1 billion UPS invests in technology per year is producing results, but what are the downfalls of telematics and other advancements? The union representing UPS workers has already set forth some demands: drivers cannot be monitored without being informed and cannot be disciplined “based solely on data.” One driver noted that it “does feel like big brother.”

Issues of security, privacy, accuracy, capacity, and the growth of software substitution in the workplace are all matters that need to be examined as IoT explodes. As IoT matures, it is wise for companies, especially those in manufacturing and logistics, to pay close attention. As reported by Gartner, by 2020, “Economic value-add (which represents the aggregate benefits that businesses derive through the sale and usage of IoT technology) is forecast to be $1.9 trillion across sectors.” With the increased possibility, reach, and data of the IoT will come complex decisions and opportunities for businesses.

Fronetics’ Kate Lee has written extensively about the Internet of Things and the supply chain. Her article, How the Internet of Things will change your world, was published in the Quarter 1, 2015 edition of Supply Chain Quarterly.

by Elizabeth Hines | Apr 1, 2015 | Big Data, Blog, Data/Analytics, Logistics, Supply Chain

A distribution center struggling with a high number of forklift truck impacts found a way to leverage big data to address a nagging, costly warehouse issue. The company had installed a telematics solution on its forklift trucks, but could not determine the cause of the impacts. The time and location of impacts were known, as well as the identity of the drivers involved, but the company still needed to pull in more data sources for an effective assessment.

Forget for a moment the potential of adopting big data analytics throughout the entire supply chain and consider instead how big data can untangle and integrate seemingly unrelated masses of data to solve small problems in a warehouse or distribution center. That’s exactly what this company did.

By analyzing the link between environmental factors inside the distribution center and the forklift impact records, the culprit was swiftly identified: fast-moving thunderstorms that caused the humidity level to rise so quickly that the dehumidifiers could not keep up, increasing the risk of drivers losing control on the slippery concrete floor. That knowledge helped the company prevent sliding accidents by using a function of the telematics solution to reduce the maximum speed of the trucks when the humidity hit a certain level.

Indeed, distribution centers and warehouses present ideal environments — microcosms — for big data applications. Modern facilities are loaded with sensors and detectors to track every pallet and every piece of material handling equipment in real-time. Managers see the benefits in increased productivity, improved inventory flow, optimized equipment usage, and more. However, for that Eureka moment, organizations should also apply big data analytics across these multiple sources of data to uncover patterns that will drive even more, and perhaps surprising, operational improvements.

Rather than looking at data in isolation, a holistic approach holds significantly more power. Managers typically keep careful track of the performance of lift trucks, batteries, and chargers. But it is not until those entities are reviewed as a single system and matched with data coming off the lift trucks that a new level of revelations can be had.

Look for big data analytics to further raise the IQ of our “smart” warehouses and DCs. Inbound Logistics sums it up this way: “Accessing the right information to make smart decisions in the warehouse is one main reason why the demand for big data has grown so much — and so rapidly — in the distribution sector.”

Do you think distribution center and warehouse managers do enough to leverage big data?