by Fronetics | Jun 17, 2014 | Blog, Marketing, Social Media, Strategy, Supply Chain

Many companies within the logistics and supply chain industries are stuck on the social media starting line. The reason – “they can’t get past the word ‘social’ and the perception it creates.” The reality is that social media is a tool that can be utilized to create value and grow your business.

This is the third in a series of articles that provides examples of companies within the logistics and supply chain industries who have moved beyond the social media starting line and have realized the business value of participating in social media.

Sourcemap: End-to-end supply chain visibility

In the wake of events such as hurricane Sandy, the Fukushima nuclear distaster, the Bangladesh factory collapse, and the horse meat scandal, businesses and consumers are increasingly demanding supply chain transparency.

Sourcemap is a social network which provides end-to-end visibility within a supply chain. Sourcemap offers supply chain mapping, crowdsourced RFIs, risks and alerts, and KPI dashboards. Launched by researchers at MITs Media Lab, Sourcemap was recently named one of Spend Matters Top 50 companies to watch.

Figure 1: What Sourcemap Offers

Sourcemap connects producers, manufacturers, and consumers for end-to-end visibility. Manufacturers can use Sourcemap to trace products down to raw materials, to manage risk, to and plan more resilient, efficient supply chains.

Consumers can use Sourcemap to learn where things come from and what they’re made of, including their social and environmental impact.

Stonyfield used Sourcemap to create an interactive sourcing map for its yogurt – to show consumers where the ingredients that go into their yogurt comes from.

Consumers simply click on an ingredient shown on the map (Figure 2) and then are shown information about the specific ingredient (Figure 3).

Figure 2

Figure 3

In the process of creating the map, Stonyfield engaged suppliers and fostered increased communication and stronger relationships. These relationships, this communication, and the ability for companies (and consumers) to know their supply chain from end-to-end is what Sourcemap wants to provide.

Sourcemap takes social media and makes it a vital supply chain tool.

by Jennifer Hart Yim | Jun 12, 2014 | Blog, Data/Analytics, Strategy, Supply Chain

This article is part of a series of articles written by MBA students and graduates from the University of New Hampshire Peter T. Paul College of Business and Economics.

Regularly tracking your relationship with your suppliers and their performance toward your expectations is critical to ensure the success of your business. One mechanism for tracking this is the supplier scorecard. A scorecard is in essence a report card for your supplier. Supplier scorecards when used effectively can help maintain a healthy supply chain and will benefit both parties. If not used effectively supplier scorecards can damage the supplier relationship and hurt both businesses.

Effective scorecards should use meaningful metrics. If it doesn’t align with business goals then it shouldn’t be measured. Easily measured variables of no importance will just cause clutter; they could also cause a supplier to focus their performance in areas that do not matter. If the metrics are not clearly defined and understood by the suppliers then it will be hard for them to adjust their performance in these areas. Another consideration is there may be things that are important to you which your suppliers have no way of measuring or attaining the performance you are asking for.

As with all business to business relationships communication is critical for maintaining and improving supplier performance. To ensure suppliers meet your needs you should communicate to them from the offset how their performance will be measured. You can even tie bonuses and penalties into their performance scores. You should be mindful that your relationship with your supplier should be collaborative; as you grow so should they. You should share the results of your scorecards with your suppliers on a regular basis and shouldn’t wait until a review to raise a concern. Another important aspect of communication is sharing your business objectives and performance data with your suppliers. This can help them to better shape their business to meet your needs as your business fluctuates.

It is important when evaluating suppliers to have a good process in place for tracking important metrics. When possible it is best to use accurate data that is understood by both you and your supplier. If you use fuzzy metrics which are subjective then improvements become difficult to measure and target. Also, tracking metrics throughout the scoring period will help to ensure the data is accurate and your scorecard reflects actual performance.

When dealing with different suppliers it is important to make sure the metrics you are evaluating are relevant to each supplier. As a result it is not recommended to use a one size fits all approach to supplier scorecards. Another thing to keep in mind is that you may be sourcing from the same supplier through multiple locations. It is important to track each of these on its own scorecard to help your supplier learn where they are doing things right and where they are falling short of your expectations.

Where I work we have several strategic supplier partnerships. The way we manage supplier relationships is through quarterly business reviews with each of our partners. In these meetings high level representation from both companies is present. We share with our partners our business results and forecasts in addition to any major company news. After sharing this information we review our scorecard process with the suppliers, show a score card comparison, take a detailed look at each rating, and then provide an overall summary.

Our scoring system looks at aspects of quality, delivery, cost, support, and inventory management. With respect to quality we look at hard numbers like failures out of the box and returns from our customers. We take into account both product quality and process quality. When it comes to delivery we measure on-time delivery, missed shipments, and lead times. Some of our customers have long term fixed cost agreements so this metric isn’t required, for others the cost fluctuates; we measure whether or not their costs are in line with our expectations. Support has several levels including technical support, order support, and special cases. Inventory management tracks how well they are able to maintain some inventory on hand for us.

Our scorecard metrics used to be scored on the basis of a five point scale from far below expectations to far above expectations. After running through several of these scorecards we determine that it was not likely to get exceeds expectations because the only time expectations could be exceeded is if our demand was well above our forecasts. Since this goal wasn’t something attainable by a supplier of their own action we adjusted our scorecard to have only three levels, from below expectations to meets expectations.

The scorecard comparison is unique to the supplier and it shows the ratings for each of the metrics for the current review period as well as four prior quarters. We display this in a color coded matrix so that it is easy to see where each metric is improving, staying the same, or regressing from period to period. For my employer these quarterly business reviews give us frequent touch points with our suppliers. This helps us to identify issues and areas for improvement to strengthen our supplier relationships and our business.

Throughout this article I have hit on several best practices with respect to supplier scorecards. I want to stress that this is just a tool. The fact that you have a scorecard system in place should not prevent you from acting immediately if issues present themselves. After all, this should be a collaborative exercise which will benefit both your company as well as your suppliers. In addition it is important to solicit internal feedback from interested parties. Supplier scorecards should be used to make decisions about whether or not to continue supplier relations or to pursue alternative suppliers.

Mike Cleary is a Software Quality Assurance Engineer at Empirix pursuing his Masters of Science in Management of Technology from the University of New Hampshire. He has over ten years of experience in testing IP and telephony solutions across a variety of platforms. In his current role he is responsible for not only ensuring Quality in the E-XMS solution but other administrative tasks such as lab configuration, VM server, and perforce administration.

by Fronetics | Jun 9, 2014 | Blog, Marketing, Social Media, Strategy, Supply Chain, Transportation & Trucking

Many companies within the logistics and supply chain industries are stuck on the social media starting line. The reason – “they can’t get past the word ‘social’ and the perception it creates.” The reality is that social media is a tool that can be utilized to create value and grow your business.

This is the second in a series of articles that provides examples of companies within the logistics and supply chain industries who have moved beyond the social media starting line and have realized the business value of participating in social media.

Long-haul truck drivers are more likely to be overweight or obese than the general public (86% v. 65%). Additionally, truck drivers are more likely to smoke, have high blood pressure, and suffer from sleep apnea than the general public. The poor health of long-haul truckers is largely due to their lifestyle. Long-haul trucking is a sedentary lifestyle. It is also a lifestyle which makes it challenging to access gyms and healthy foods.

The cost of poor health is enormous – for truckers and for their employers. The estimated annual health care costs of obesity-related illness are $190.2 billion, or nearly 21 percent of annual medical spending in the United States. Looking specifically at the trucking industry – a study published in the Journal of Occupational and Environmental Medicine found that obese truckers had an annual average total health care cost of $1,944, compared with $1,755 for overweight truckers and $1,131 for normal-weight drivers. A sleep apnea screening and treatment program conducted by Schneider National identified 350 drivers who required treatment. Treating these drivers not only improved their health, but it also improved the company’s bottom line – over a one year period, Schneider National saved $530 per month per driver in insurance costs and saw a 71 percent reduction in accidents involving those drivers during the same period.

An article in Today’s Trucking shares the story of Jason Janneta a 42 year old trucker who had been driving for 20 years and was a poster boy for the statistics – overweight and unhealthy. Fed up, he decided to make a lifestyle change. Within six months of embracing a healthier lifestyle he had lost 80 pounds. During this period he had also taken to Twitter to share his experience and to motivate other truckers to adopt a healthier lifestyle, lose weight, and improve their health.

Tweeting as @urbanhauler with #fittrucker, Jannetta captured the attention of other truckers (he quickly grew his followers to more than 1,500) and the attention of Jared Martin, the President of Speedy Transport.

Martin recognized the value of Jannetta’s efforts and of #fittrucker – healthier individuals, a healthier bottom line, and opportunity to attract new drivers.

According to Martin:

“I really enjoyed a lot of his posts and what he was trying to do for the industry, so we brought him in for a meeting.”

The two discussed the role of health and fitness on the future of the transportation industry. The next day, Martin offered Jannetta a job at Speedy Transport – Driver Trainer and Wellness Advisor. Martin accepted the position and now tweets for @speedywellness where he brings “#trucking and #fitness/#wellness together.”

Speedy Transport is one company which has recognized social media as a business tool and has moved far beyond the social media starting line. The Twitter profile of @speedywellness rightly points out “we #ChangeTheGame of #Trucking.”

by Jennifer Hart Yim | Jun 5, 2014 | Blog, Manufacturing & Distribution, Strategy, Supply Chain

This article is part of a series of articles written by MBA students and graduates from the University of New Hampshire Peter T. Paul College of Business and Economics.

By now we have all heard the story of GM’s faulty ignition switches that are being linked to thirteen deaths and thirty one front-end collisions. The ignition switches in car models: Chevy Cobalt; Chevy HHR; Pontiac G5; Pontiac Solstice; Saturn Ion; and Saturn Sky, lacked the torque specs required by GM engineers. Heavy key chains, bumpy roads, or an accidental knee hit were all reasons reported that could cause the ignition switch to rotate to the off or idle position. Once this happened, the driver would lose control and the air bags would fail to deploy if a front end collision occurred. A total of 2.6 million vehicles were recalled, of that 2.2 million were in the United States. For this type of recall, GM was not requiring vehicles to go back to the manufacturer or be disposed. Rather, a more robust key ignition was distributed to all authorized GM dealerships and customers were told to bring their cars to the local dealership and a new ignition switch would be put in for them.

Despite the massive recall and all the negative publicity that goes along with such an event, GM still posted positive numbers in their quarterly earnings. GM posted an operating income of $0.5 billion for 1Q14, which is included the $1.3 billion recall-related charge. Furthermore, GM controlled approximately 17% of the U.S. market share. After the ignition switch incidents started to gain traction, GM swore to reorganize their global engineering department, and they did. So, if GM’s sales profitability is surviving, their negative press contained, and their market share intact, what exactly went wrong?

Two-thirds of General Motors automotive costs in 2014 are from supplier sourced parts. However, this was not always the situation. Back in 1999, GM underwent an extensive effort to disassemble their vertical integration in hopes of reducing overall costs. At this time, Delphi Automotive was owned by GM, but separated during the same year. For decades, GM was Delphi’s only customer, and even when Delphi executives knew GM was going to make them a public company, they were only able to move 22% of their business to other customers. When GM officially made Delphi a public company, 82.3% of their shares went to GM shareholders. That means that only 17.7% of Delphi was sold to public investors. In order to survive as a company, Delphi had to start making cost reduction decisions. To do this, companies often lay off employees and make cheaper parts, Delphi was no different. Now during this same time period, GM executives were focused on focused on costs reductions and were driven by numbers, hence the selling off of Delphi. It should be noted that if a company sells off their single largest parts supplier, fully aware that the move may cause the supplier to go belly up, there will be some strained relationships. Delphi was now thrown into a position where they must compete with other parts suppliers for GM’s business. An important part of the deal GM made when selling off Delphi was to keep all current supplier contracts. In addition, GM gave Delphi the opportunity to match any competitor’s bid until 2002. The earliest model of a recalled GM car was 2003.

Strained supplier relationships are not ideal for business, but should not affect the quality of a product, such as an ignition switch. Let’s fast forward to 2008. Delphi had declared bankruptcy three years prior and GM was beginning to pull them out of their financial burden. A contract was found between GM and Delphi that was drafted in 2008. The document is a little difficult to follow, but there are a few interesting lines in Section 5.09 Product Liability Claims. It appears that, GM said they would share the blame with Delphi for any claims against them. However, GM would not be held responsible if one of Delphi’s parts, or a part made for Delphi by a third party, fails. The contract continues on to say that GM would pay any legal fees if a claim was made against Delphi, but Delphi must defend GM through a potential lawsuit. This contract was drafted and signed in 2008, during which Delphi was bankrupt, so it appears they had little negotiating power.

This raises concerns specifically about the ignition switch specs. It came out that GM officials knew the ignition switch they purchased from Delphi was not up to their standards. After some more research, an email transaction between Delphi officials in regards to the plunger, the vital part that holds the key slot in place with a spring, and the ignition switch. At the end of the document, the original engineer drawings are attached. From the technical drawings it can be seen that Delphi did in fact outsource the design specs, and possibly the manufacturing, for the plunger design. Another document, that was preceding the email transaction, appears to inform GM that the plunger part was changed and the responsibility of the supplier is “closed”. This could have been a legal move meant to save Delphi if any claims were made related to these parts.

After all of this evidence, where does the blame lie? It would appear that GM used their powers to force Delphi into a contract that held them responsible for any claims against their products. While Delphi did warn GM that the torque requirement for their ignition switch did not meet GM’s requirement, it is unclear whether or not a verbal warning will play into the legal battle. This case is currently ongoing, and it will be interesting to see how it plays out.

Connor Harrison holds a B.S.M.E and MBA from the University of New Hampshire.

by Fronetics | Jun 3, 2014 | Blog, Marketing, Social Media, Strategy, Supply Chain, Transportation & Trucking

Many companies within the logistics and supply chain industries are stuck on the social media starting line. The reason – “they can’t get past the word ‘social’ and the perception it creates.” The reality is that social media is a tool that can be utilized to create value and grow your business.

Over the next four weeks I will be providing examples of companies within the logistics and supply chain industries who have moved beyond the social media starting line and have realized the business value of participating in social media.

Using social media to move freight

Transportation logistics is vital to the supply chain and logistics industries. For companies within these industries; however, transportation logistics can prove to be challenging to navigate and can prove challenging to the bottom line.

MercuryGate International Inc. and Con-way Inc. are two companies that have used social media to turn transportation logistics on its head – they use social media to move freight.

TweetLoad

Con-way Multimodel, a division of Con-way Inc., launched TweetLoad™ in 2010. TweetLoad enables carriers to access available loads from Con-Way Multimodel via Twitter. Carriers who follow @ConwayTweetLoad on Twitter are able to see the latest available shipments as well as links to additional information on the company’s link board. Load information is updated on Twitter every 15 minutes, meaning that carriers who follow @ConwayTweetLoad have real-time information on available loads.

Figure 1: Conway TweetLoad

Bill Graves, president, American Trucking Associations (ATA): “With this novel use of Twitter, Con-way Multimodal is leading the industry in maximizing the best features of new technology to improve their processes. This is a great example of how innovative transportation companies can make it easier for carriers to do business with them, which will be a benefit to our industry overall.”

View a YouTube demonstration of TweetLoad at www.youtube.com/watch?v=0zL7h7kTU1M.

Freight Friend

In 2011 MercuryGate International Inc. launched Freight Friend. Freight Friend is a free relationship-based full-featured load and truck internet posting service for shippers, brokers and carriers. Freight Friend creates a private network between transportation partners, and utilizes technology to automatically identify appropriate matches. The combination of the technology utilized and the relationship-based nature of Freight Friend allows companies to have real-time visibility to book trucks and find freight with companies they trust.

The Freight Friend concept is shown in Figure 2.

Figure 2: Freight Friend

“FreightFriend is perfect for carriers, shippers, brokers, 3PLs and freight management firms who only want to share information with companies they trust. They can keep their current information in one place, knowing that friends – and only friends – will have constant access. While public load boards fill a real need, they come at a cost – a lot of unknown companies bidding to carry the freight. Private boards are often useful too, but they’re inconvenient to carriers with multiple clients asking them to check their bid portals. FreightFriend solves the dilemma with a single service where carriers can easily communicate with all of their clients and brokers can find available capacity from carriers they trust.”

Freight Friend is fully integrated into MercuryGate’s TMS and Carrier Management System (Carma). Freight Friend is also available to integrate with other TMS providers.

by Jennifer Hart Yim | May 28, 2014 | Blog

This article is part of a series of articles written by MBA students and graduates from the University of New Hampshire Peter T. Paul College of Business and Economics.

In an increasingly globalized world the complexity in a firm’s supply chain has been getting bigger as it has spread over the whole globe. The risks of such a large supply chain have increased exponentially as the exposure to unforeseeable events, natural and man-made, have multiplied. Investing time and money in a Business Continuity Plan and hence building a resilient and flexible supply chain can not only become a competitive advantage but it is also critical for a firm’s survival.

Supply Chain Disruptions

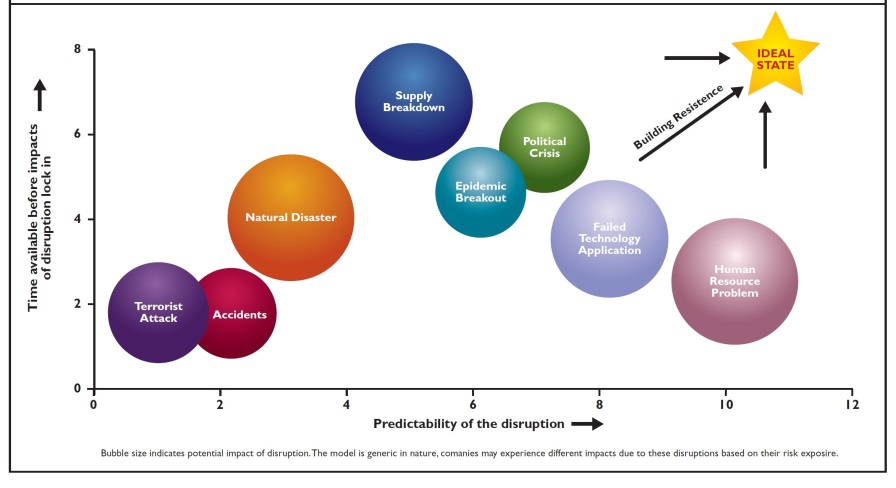

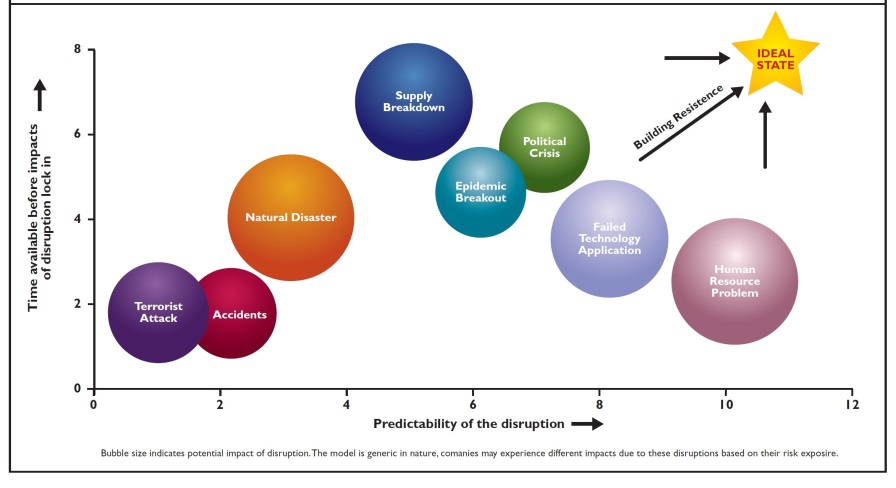

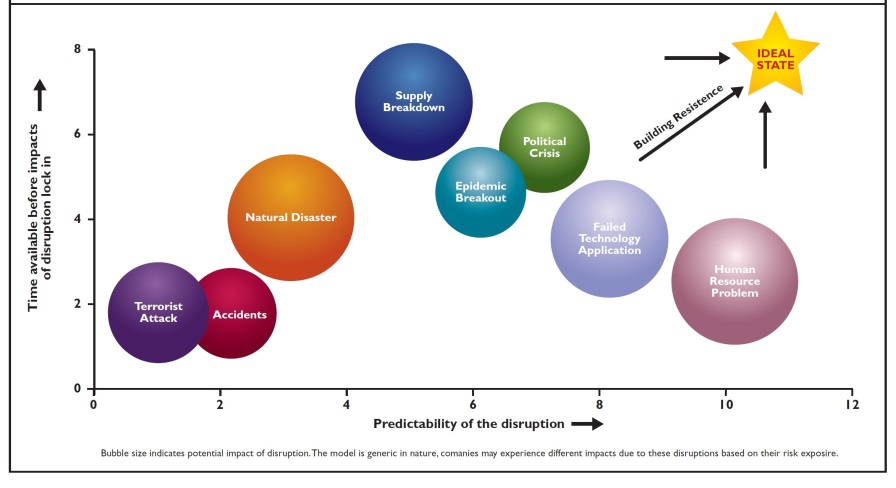

Supply chain disruptions happen for various reasons but always cause and end in an imbalance of the supply and demand of products. The magnitude of such events can go from insignificant to the size where the existence of the business is threatened. As shown in Graph 1 the disruption can have immediate impact, such as a power outage or fire in a factory, or take more time to set in. A union labor strike or the outbreak of an epidemic virus in a certain region could describe more predictable examples.

Graph 1: Supply chain disruptions categorized by predictability and time available after impact.

Where disruptions in tier one suppliers always have a direct impact of a firm’s supply chain, tier two and three disruptions can be buffered and show their effects only when the disruption gets to a certain size and reach. As an organization can never be fully in control of its business environment and supply chain it is safe to say that every business will sooner or later face some sort of disruption. Disruption can be costly. In 2013 15% of the disruption cost more than one million US dollars. Knowing this, businesses will benefit from developing a Business Continuity Plan.

Business Continuity Plan

A Business Continuity Plan is a road map for continuing operations after and/or during a disruption. The main components of a Business Continuity plan are:

- Business impact analysis

- Design of solution/remedy

- Implementation

- Testing

- Maintenance/feedback

Business Impact Analysis

The analysis of the severity of the impact to the business will help prioritize further action and the design of the solution. The analysis differentiates the critical and non-critical events and lists them accordingly. The criticality can be based on cost, ability to continue the operation, brand reputation and also laws. A threat and risk analysis combined with various impact scenarios will be the basis for the design of a solution.

Design of a solution/remedy

The solution design part of the Business Continuity Plan comes up with the most cost-effective recovery solution. Additionally, it identifies authorities for decision making during disruptions (crisis management command structure) as well as which contracts, documents and contact lists have to be available as a hard copy outside the facility. On the operational level this includes but is not limited to:

- Backup power

- Logistic routes

- Back up suppliers and lead times

- Warehouse/distribution center locations

- IT back ups

- Talent and skill succession planning

Implementation

The implementation phase involves strategic decisions, such as policy changes and training of the company’s own staff, as well as the communication of the Business Continuity Plan to suppliers and customers. The acquisition of materials and systems are part of the implementation. IT infrastructure can be moved to cloud computing for data safety and modern systems are extended to allow visibility into the supply chain. This can go as far as the second or third tier.

Testing

Testing will show if the elaborated solutions will satisfy the requirement. Testing can be as simple as an evacuation drill or as complex as a mock recall.

Maintenance/feedback

The first step of maintaining the Business Continuity Plan is to constantly monitor the situation around the identified risks and threats in the Business Impact analysis. This will also help foresee possible disruptions and might allow acting ahead of time to prevent a bigger impact. The Business Continuity Plan must evolve with the threats and the company development/growth. This requires constant updating and testing as well communicating to the staff, important clients and suppliers. More significant changes might even require updating of organization structures.

Feedback after a disruption event can be as vital to a Business Continuity Plan as its design. The reevaluation of the supply chain will allow assessing the effectiveness of the plan, the resilience of the system as well as the validity of the sourcing strategy. Collecting all these findings in a report will allow making sustainable changes. Such reports can also be helpful when negotiating terms and conditions with suppliers and/or insurance providers.

Summary

The design and implementation of a Business Continuity Plan is a big undertaking for a firm. The likelihood of disruptions in the supply chain and in other business processes is increasing with globalization. It is recommended that the firms start somewhere and attack the low hanging fruit. With a Business Impact Analysis the risks to the business can be categorized and prioritized. This knowledge can be used for the development and growth of the company as preventive measures can be built in new structures. The importance of monitoring the threats and learning from disruptions can become a competitive advantage and secure the existence of the business. While Business Continuity Plans can be structured simple and still cover the five components there is also professional education and training as well as certifications to support the continued success of the business.

Dario Cavegn hold a Master’s of Science degree from ETH Zurich in Switzerland. Currently he is working as a Manufacturing Manager for Lindt & Sprungli (USA) Inc., and is an MBA candidate at the Peter T. Paul College of Business and Economics. He can be reached via email at [email protected].