by Fronetics | Aug 12, 2014 | Blog, Content Marketing, Marketing, Social Media, Supply Chain

Connectivity, mobility and accessibility are game changers for business. Companies that recognize this and adapt accordingly will succeed, companies that don’t will not.

Unnovation

Olaf Swantee, CEO of EE, calls this refusal to innovate “unnovation” and defines it as the following:

If unnovation ever made it into the Oxford English Dictionary, I believe the description would be something along the lines of “unnovation (noun) … the refusal to identify, create, embrace or adopt new ideas, leading to the unnecessary and un-timely end to a business, which is ultimately overtaken by external progress.

What are companies who have fallen prey to unnovation? Yell (Google), Borders (Amazon), and Blockbuster Video (Netflix) are just three examples.

Companies within the supply chain, and the supply chain industry in general, are at risk of falling prey to unnovation despite being in a prime position to innovate.

Unnovation and the supply chain

KPMG’s 2013 Global Manufacturing Outlook reported that the US manufacturing sector “seems primed for an era of ‘hyper-innovation,’ in which companies develop not only new products, but also entirely new ways to build them.” Unfortunately, companies within the manufacturing sector are not primed for innovation. KPMG found that 44 percent of survey respondents reported that they still use “old” technologies such as email, fax, and “snail” mail to manage their supply chains.

Similarly, the supply chain industry has been slow to participate in social media and to invest in creating a strong online presence. The primary reason: a lack of understanding of the business case or value.

Participating in social media and investing in creating a strong online presence are fundamentally different from the traditional strategies which companies within the supply chain industry have employed to attract new customers, foster relationships with current customers, communicate with partners, and grow their bottom line. Because of the stark contrast between “old” and “new,” companies do not recognize how these strategies can positively impact their bottom line and therefore decide to steer clear – they feel engaging is too risky. The reality is that not participating is risky; not participating is unnovation.

These companies embrace change

Keychain Logistics

Companies that choose to unnovate will be eclipsed by companies who embrace the world of mobility, connectivity and accessibility. Keychain Logistics is one company that has decided to embrace change.

Bryan Beshore, Keychain’s founder, recognized the changes taking place and decided not just to embrace them, but to also capitalize on them. Keychain leveraged the ideas of mobility, connectivity and accessibility and created a new way for the freight transportation industry to conduct business. Keychain is a marketplace that connects drivers directly with shippers – and is available via mobile app.

Keychain has also become an active participant on social media. This participation has enabled the company to shape their offering with a solid understanding of what people want from a transportation provider. Furthermore, Beshore notes that social media has helped grow their business: “From phone calls to interviews, crowdfunded campaign partnerships, and beyond, social media has certainly helped us grow our business.”

Cerasis

Another company that has been successful – Cerasis. For 15 years the freight logistics company used traditional sales and marketing strategies. This strategy worked; however, the company recognized that if it were going to remain competitive and grow it needed to adapt. The company launched a digital, social media, and content marketing strategy. The strategy lead to an increase in website traffic of close to 670 percent, an increase in search visits by close to 2,190 percent and, most importantly, the company acquired 35 new customers – a significant number for the industry.

Swantee believes that if companies choose unnovation, “Ultimately, it could lead to disastrous consequences for their businesses, their staff and their future.” I agree. If a company wants to remain relevant and competitive, and if a company wants to grow – it needs to recognize that connectivity, mobility and accessibility are game changers for business.

by Jennifer Hart Yim | Jun 26, 2014 | Blog, Internet of Things, Logistics, Manufacturing & Distribution, Marketing, Social Media, Strategy, Supply Chain

This article is part of a series of articles written by MBA students and graduates from the University of New Hampshire Peter T. Paul College of Business and Economics.

Supply Chain Management will use the Internet of Things to improve factory workflow, increase material tracking, and optimize distribution to maximize revenues.

“Clap on “(clap, clap), “Clap off” (clap, clap), “the Clapper”!!

When introduced in 1986, “The Clapper” light switch was considered a significant breakthrough in home automation. Today, with advances in communication, sensors, and internet-connected devices, you can change the temperature of your home, your lights, appliances, and security system all from your smartphone — from anywhere in the world. This is just one simple example in the growing “Internet of Things” technology. The potential is enormous, not just in home automation but in industrial applications like manufacturing and distribution.

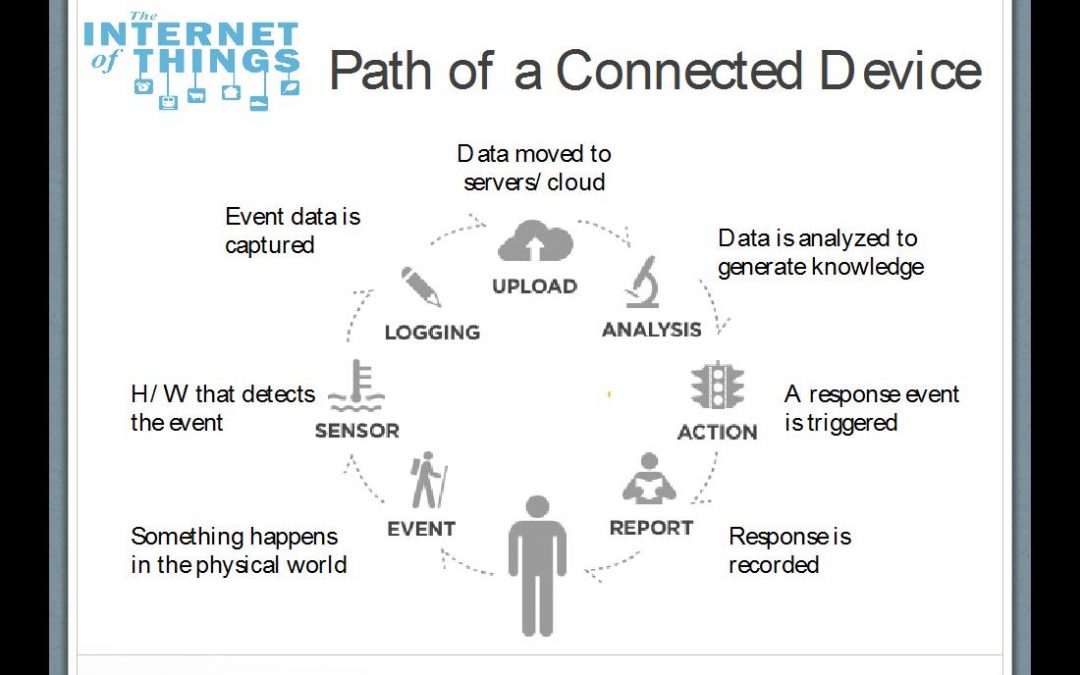

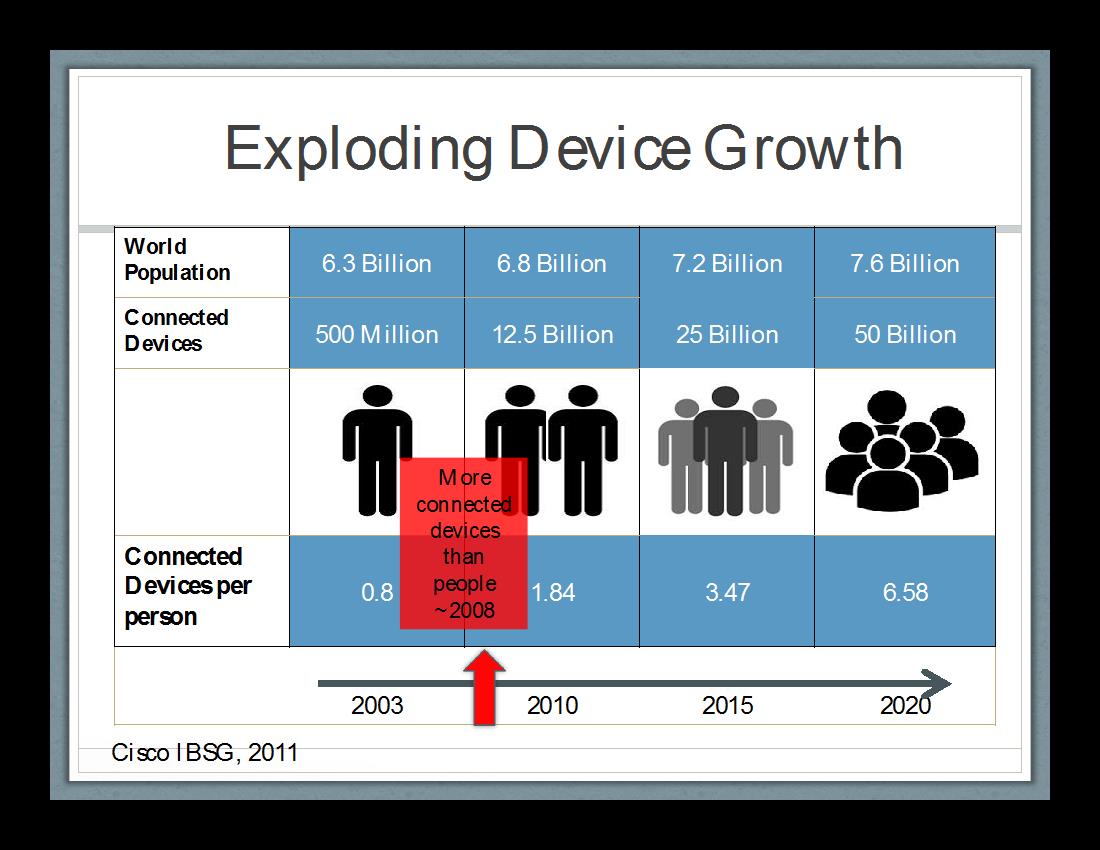

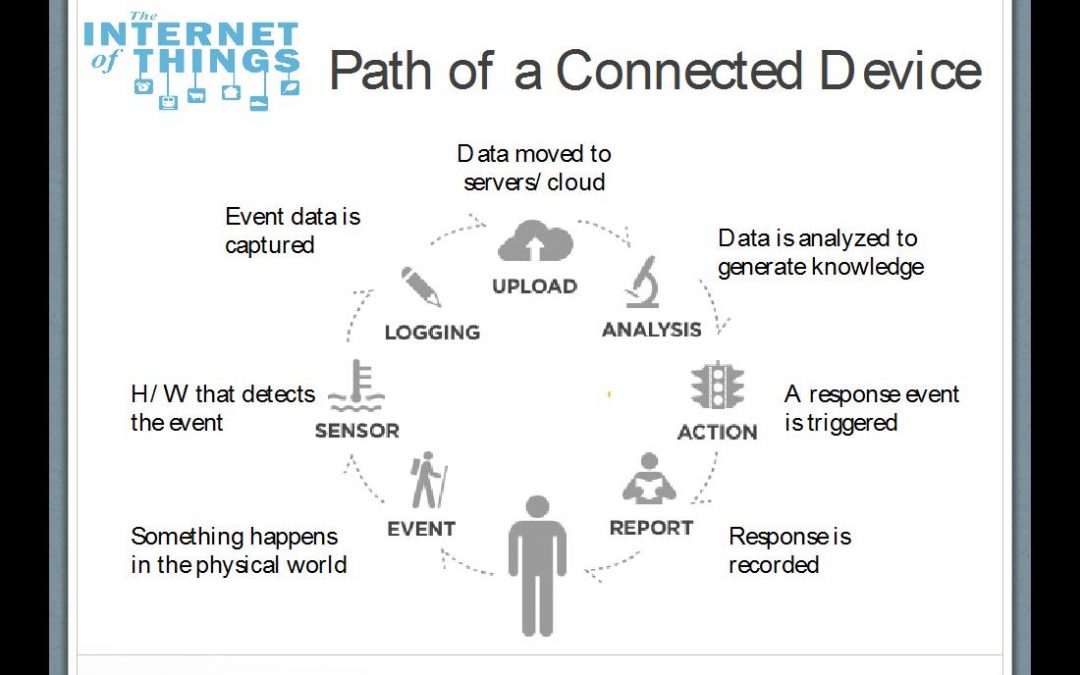

The Internet of Things (IoT) is broadly defined as the merging of the physical and digital worlds. It’s a scenario in which people and/or objects can be uniquely identified with the ability to share information over a network without any actual conscious intervention. The data is automatically transferred, analyzed, and used to trigger an event. Figure 1 below demonstrates how one of these devices functions and interacts with the Internet and other devices.

Figure 1.

The IoT and Supply Chain Management

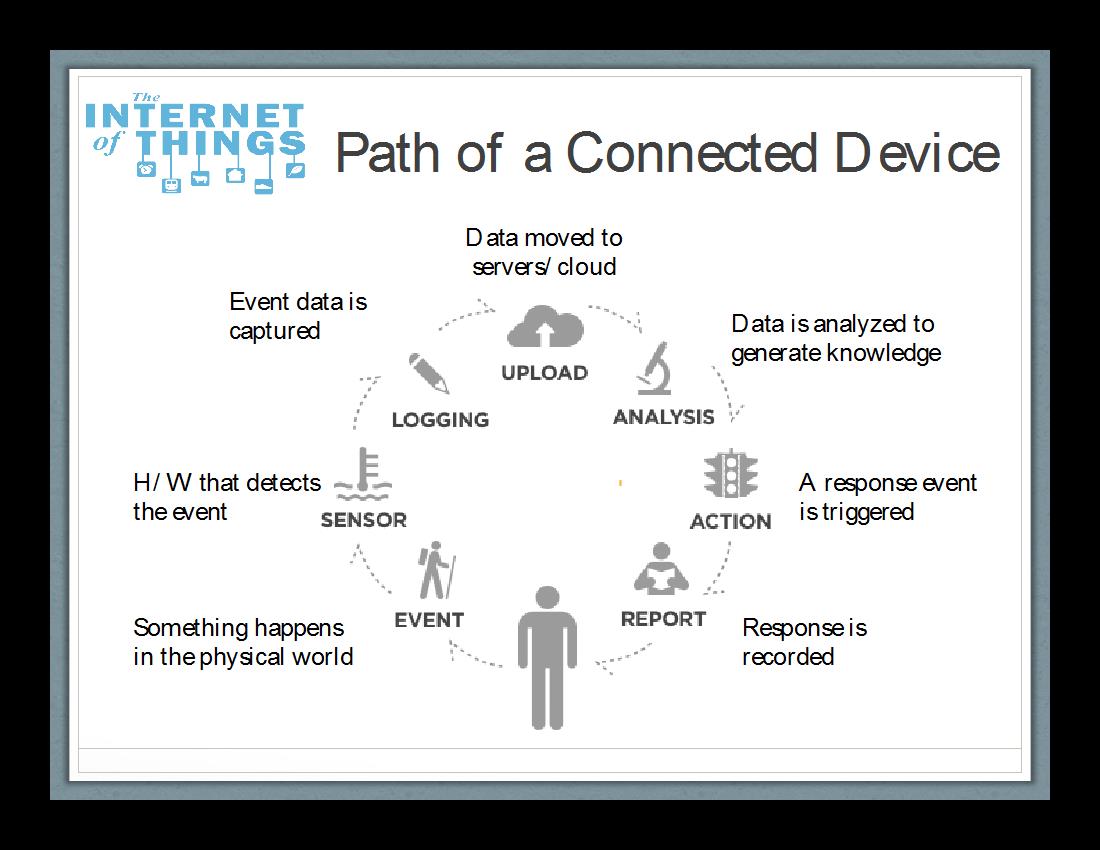

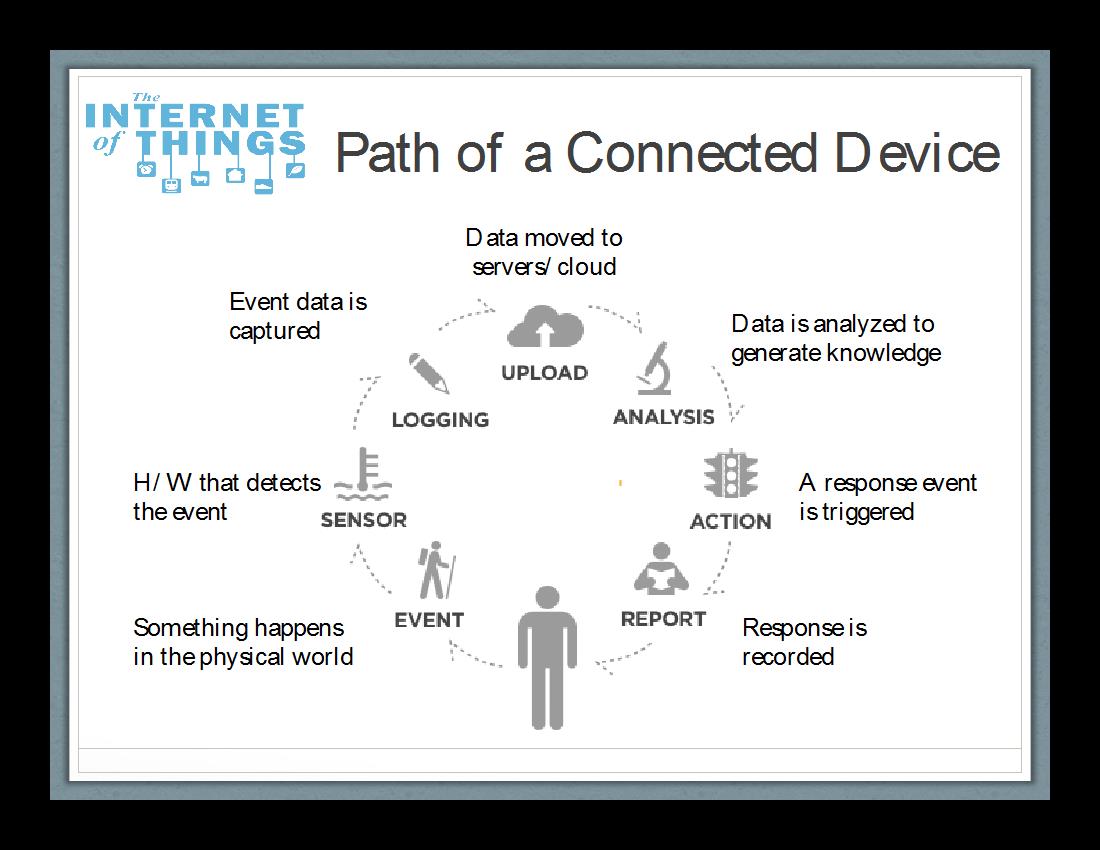

While many of us may be familiar with recent advancements in home automation, like the Nest thermostat, the real impacts of IoT will be in Supply Chain Management. Recent reports by Cisco, IDC and Gartner all claim that a significant increase in the number of devices making up the Internet of Things will have a profound impact on how future supply chains will operate. The 2011 Cisco report predicts there will be 50 billion connected devices globally by 2020, or about 6.5 devices for each person, up from only approximately 2.5 today (see figure 2). More active devices means more available data — to the point where they will be ubiquitous and transparent in our every day lives.

Figure 2.

Impacts to supply chain will be broad and far-reaching, utilizing Big Data to gather and analyze information across the entire process.

Some IoT devices have been in place for some time, such as commercial telematics now used in trucking fleets to improve logistics efficiency. Other commercial type applications — like fabrics that use sensors within clothing and industrial fabrics to monitor human health or manufacturing processes — are just being developed now.

Mark Morely of GSX, a leading provider of monitoring and management solutions, recently discussed three key impacts he believed IoT would have on the Supply Chain industry: Pervasive Visibility, Proactive Replenishment, and Predictive Maintenance. This is a great way to explain the immediate benefits, so I will summarize Mark’s description and expand with some real-world examples.

Three key impacts the IoT will have on the supply chain industry

1) Pervasive Visibility

Mark describes this as the ability to track and monitor a shipment in real time using a combination of sensors (RFID), connected devices, and communication channels (3G/4G, GPS, internet). It provides the ability to have real-time transit status, including location, temperature, and diagnostics — far more information than legacy infomatics provided.

One great example I found is from a company called Purefresh, who are at the cutting edge of Supply Chain IoT technology. They offer not only real-time shipment condition tracking, but also the ability to model and develop transit routes to optimize freshness in perishable cargo — taking into account environmental elements, such as ozone, atmospheres, and temperature. They indicate that an estimated “30% to 50% (or 1.2-2 billion tons) of all food produced on the planet is lost before reaching a human stomach.” IoT advancements will not only better optimize transit flow but also better serve humanity.

2) Proactive Replenishment

It’s the capability to automatically recognize the need to order and restock a product on a “machine-to-machine” basis, reducing the need for human interaction. The most common example is that vending machines will know when it’s out of or low on a Snickers bars and immediately trigger an alert to reorder them, instead of waiting for a service person to check on the vending machine and reorder products manually. The result is less human intervention, quicker replenishment, better sales forecasting and ultimately increased revenues. Oh, and many more happy office workers who really need a mid-afternoon sugar rush!

Opportunities for this technology go far beyond the candy vending machine though. Industries with time critical inventories like hospitals and pharmacies can better maintain supplies by supplementing human inventory control with real time use tracking. A much less critical but more broadly used application comes from Coke’s Freestyle fountain soda machine. It’s about the same size as the existing vending machines but it can dispense 126 kinds of flavors, offering an almost infinite amount of combinations. It uses Radio Frequency ID (RFID) cartridges that store the concentrated syrups in the machine. The RFID chips detect how much of each syrup it has and what combinations are being used. When it detects that it needs supplies, it transmits the information to both Coca-Cola and the storeowner including what has been sold, a record of when sales occurred, troubleshooting information, and service data. As a result, soda sales and customer satisfaction increases, all with less effort by the storeowner.

3) Predictive Maintenance

This application is closer to the true machine-to-machine communications the IoT was intended for. From large-scale manufacturing to diagnostics on the family minivan, predictive maintenance utilizes sensors and connected devices to monitor and react to issues. This self-diagnosis capability can detect a potential issue before there’s a failure, order a replacement part, and even schedule maintenance to avoid costly downtime.

Not only does predictive maintenance help keep factories running longer and the family minivan from unexpectedly breaking down, it can improve efficiency throughout the whole supply chain. If equipment manufacturers constantly receive service data from factory equipment, they can better trend problems and focus on those issues for future products. Parts depots can better forecast inventories and determine consistent safety stock levels. IoT, in this example, is a true B2B (business to business) — automating the communication between businesses on every link of the chain.

In relation to home automation, predictive maintenance will become integrated into our everyday lives. Appliances will become smarter, more efficient, and easier to monitor. Internet-connected sensors will be embedded into everything from refrigerators to washers/dryers and HVAC systems. So much so that companies like GE are investing heavily into these technologies, in both commercial and industrial applications. These connected appliances will perform self-diagnosis, determine the most cost-efficient time to operate, and even automatically order maintenance parts like furnace filters when needed. Imagine getting an alert on your smartphone that your forced hot air furnace needs a new air filter, and it has already been ordered through your Amazon account. It just saved you effort in remembering to check the filter and ordering it — leading to a cleaner, longer-lasting, and more efficient furnace.

So, why isn’t IoT here yet?

It’s close but there are still hurdles to overcome. In recent years, advances in sensor technologies, 4G communications, and cloud computing has made achieving Internet of Things capabilities even more possible. But for companies in the Supply Chain to leverage these opportunities, they will need to expand investment into cloud-based platforms that can support scalable devices and data-analysis services.

Critical to IoT’s success will be the necessary “middleware” software communication protocols to link all these devices. Companies like ProSyst and open-source SW projects like OPENIoT are pioneering these capabilities. But even with this progress, agreements on industry standards will be key to long-term platform success.

Having a common IoT protocol will be necessary to link the physical and digital worlds on a consistent and economical basis. Understanding the need for standards and common architectures, Intel has led the way by recently creating the not-for-profit Industrial Internet Consortium (IIC) with other vested companies like AT&T, Cisco, GE, and IBM. The connected Supply “Chain” will become exponentially longer once these common standards are in place.

The Internet of Things trend is quickly approaching and will impact the way we live and work through increased productivity and efficiency. Supply Chain Management will continue utilizing these advanced technologies to improve factory workflow, increase material tracking, and optimize distribution to maximize revenues.

In 1986, I recall how innovative I thought the Clapper was — I couldn’t have imagined how connected we would become only 28 years later. And the next 28 will be sure to amaze.

Steve Mondazzi is a Principal Master Planner in the Defense Contracting industry. After 20 years’ experience in project management and schedule development, he decided to further his education by recently earning a Masters in Technology Management at the University of New Hampshire. He’s a certified PMI Project Management Professional, an entrepreneur, and an avid lover of all things technology. He currently resides in Massachusetts with his wife, two teenagers, and an excessive collection of headphones. Steve can be contacted via his Twitter account @schedulepro or through LinkedIn.

Related posts:

by Fronetics | Jun 23, 2014 | Blog, Logistics, Marketing, Social Media, Strategy, Supply Chain

Many companies within the logistics and supply chain industries are stuck on the social media starting line. The reason – “they can’t get past the word ‘social’ and the perception it creates.” The reality is that social media is a tool that can be utilized to create value and grow your business.

This is the fourth in a series of articles that provides examples of companies within the logistics and supply chain industries who have moved beyond the social media starting line and have realized the business value of participating in social media.

Cerasis is a top freight logistics company and truckload freight broker. During the company’s first 15 years it focused on traditional sales and marketing strategies and relied heavily on referrals. This strategy worked. Cerasis acquired new customers, retained current customers, and realized positive growth. However, Cerasis was not viewed as an industry leader, and brand awareness was low.

In 2012 Cerasis decided to participate in social media and launch a content marketing strategy.

Cerasis began actively blogging, and began using Twitter, LinkedIn, Facebook, Pinterest, and Google+. The company quickly became seen as a leader within the industry, and brand awareness increased dramatically.

Within 15 months the company received 71 leads from search engines, 65 leads from social media, and 52 leads from webinars. Even more impressive, within 15 months the company gained 35 customers (one customer within the freight logistics industry can mean a lot of revenue).

The results show that Cerasis is no longer on the social media starting line – rather, Cerasis is now a leader, not only in the freight logistics industry, but also in using social media as a business tool.

by Jennifer Hart Yim | Jan 29, 2025 | Logistics, Paid Advertising

Having a strong digital presence is no longer optional. Pay-Per-Click (PPC) advertising is a powerful tool for logistics companies looking to quickly generate quality leads and expand their client base.

Here, we walk you through everything you need to know about implementing a successful PPC strategy for your logistics business.

Why PPC Matters for Logistics Companies

The logistics industry operates in a highly competitive space where timing and visibility are crucial. PPC advertising offers several unique advantages for logistics companies:

- Immediate visibility in search results when potential clients are actively searching for logistics services

- Precise targeting capabilities to reach specific industries, locations, and decision-makers

- Measurable ROI through advanced tracking and analytics

- Flexibility to adjust campaigns based on seasonal demands and market changes

Key PPC Strategies for Logistics Companies

1. Strategic Keyword Selection

Success in PPC begins with targeting the right keywords. For logistics companies, focus on:

Transportation-specific terms:

- “freight forwarding services”

- “international shipping solutions”

- “supply chain management”

- “warehousing and distribution”

Location-based keywords:

- “[city] logistics company”

- “shipping services in [region]”

- “local freight forwarding”

Service-specific terms:

- “temperature-controlled shipping”

- “hazmat transportation”

- “last-mile delivery solutions”

2. Creating Compelling Ad Copy

Your ad copy needs to address the specific pain points of your target audience while highlighting your unique value proposition. Consider these elements:

- Include relevant certifications and compliance standards

- Emphasize your experience and track record

- Highlight specialized services or equipment

- Showcase your geographic coverage

- Include clear calls-to-action (CTAs)

3. Landing Page Optimization

The success of your PPC campaigns heavily depends on your landing pages. Ensure they:

- Load quickly and are mobile-responsive

- Feature clear value propositions above the fold

- Include trust indicators (certifications, client logos, testimonials)

- Offer multiple contact options

- Contain relevant content that matches the ad’s promise

4. Advanced Targeting Techniques

Maximize your ROI by utilizing advanced targeting options:

Geographic Targeting:

- Target specific service areas

- Adjust bids based on location performance (this one has proven to be particularly successful for our clients)

- Focus on high-value markets

Audience Targeting:

- Create custom audiences based on website visitors

- Target similar audiences to your existing clients

- Depending on your services, you may be able to use in-market audiences to target

Device Targeting:

- Optimize campaigns for both desktop and mobile users

- Adjust bids based on device performance

- Create device-specific ad copy

Measuring and Optimizing Your PPC Campaigns

Key Performance Indicators (KPIs)

Track these essential metrics to measure campaign success:

- Click-Through Rate (CTR)

- Conversion Rate

- Cost Per Lead (CPL)

- Return on Ad Spend (ROAS)

- Quality Score

- Average Position

Optimization Strategies

Continuously improve your campaigns by:

- Regularly reviewing search term reports to identify new keywords

- A/B testing ad copy and landing pages (even changing one word could improve your CTR)

- Adjusting bids based on performance data

- Optimizing for mobile experience

- Refining audience targeting based on performance data

Common PPC Mistakes to Avoid

Please, don’t do these. These things waste your budget:

- Neglecting negative keywords

- Using overly broad match types

- Ignoring mobile optimization

- Not tracking conversions properly

- Failing to test ad variations

- Overlooking quality score optimization

Budget Planning and Management

Effective budget management is crucial for PPC success:

- Start with a conservative budget to gather data

- Allocate more budget to top-performing campaigns

- Consider seasonal trends in the logistics industry

- Set aside budget for testing new approaches

- Monitor and adjust bids regularly

Future Trends in Logistics PPC

Wanna be with the cool kids? Stay ahead of the curve by testing these emerging trends:

- AI-driven automation in campaign management (yes, even daily budget management)

- Voice search optimization

- Enhanced audience targeting capabilities

- Integration with CRM systems

Conclusion

Remember that PPC is not a “set it and forget it” solution. Regular monitoring, testing, and optimization are essential for maintaining and improving campaign performance over time.

Need help with your logistics company’s PPC campaigns? Contact our team.

Read more:

by Jennifer Hart Yim | Sep 13, 2024

A SUPPLY CHAIN marketing agency Don’t waste time getting a general agency up to speed We’re a supply chain marketing agency focused solely on marketing for the supply chain industry. Get thoughtful, compelling campaigns created by a team who understands your...