by Fronetics | Sep 30, 2015 | Blog, Marketing, Social Media, Strategy, Supply Chain

The social economy is estimated to be $1.3 trillion U.S. dollars annually. Social media is more than a collection of personal commentary, photos, and inspirational quotes. Increasingly, social media creates an opportunity to gather information, and social media is becoming a useful tool for businesses to connect with other businesses and clients. Although Facebook is notorious for gathering information, social media companies are not the only companies who can gather intelligence.

Data Gathering

Gathering of intelligence has never been easier. Although there are still traditional indicators of sales and traditional feedback loops, the age of social media allows for swift collection of intelligence. According to McKinsey, “Analysts typically spend 80 percent of their time gathering information before they begin to analyze it. Social intelligence radically alters this process. Numerous tools allow analysts to create dynamic maps that pinpoint where information and expertise reside and to track new data in real time.”

Capturing the Consumer

Collecting information from your consumers online— the good, the bad, and the dirty— can help you understand consumer sentiment around brands. By searching for key words or terms you may improve sales strategies, product placement, or understand demand cycles.

Do you want to see what clients and consumers say about you and your products, about their reliance, frustration, appreciate of your role in the supply chain? You should! But you can also have a look at what is trending, what your competitors are doing, and how you can gain traction through social media. The window is a unique opportunity for you. If your competitors are garnering more views, figure out why. Do they highlight their employees? Do they link directly to items for purchase? Do they use keywords you’re not using? Are they presenting themselves as leaders in the industry by blogging?

Storm Surge

Storms happen, and they’re stronger than ever. Natural disasters will never cease. Accidents happen. There’s no fix-all, no cure for these things, but there are new ways to manage these challenging moments when they strike. In March 2012, the Red Cross announced the creation of a social media crisis monitoring center called the American Red Cross Digital Operations Center.

When Hurricane Sandy hit the Eastern Seaboard, the Red Cross was able to see how valuable social intelligence can be. According to an article in Fast Company, How the Red Cross Used Tweets to Save Lives During Hurricane Sandy, “During the week of Hurricane Sandy, the Red Cross tracked more than 2 million posts and responded to thousands of people. In the end, 88 social media posts directly affected response efforts—a fairly significant shift of resources.”

While people lost power during Hurricane Sandy, many still had internet access on their phones. They could access news updates, connect with loved ones, and ask for help through social media. According to the Pew Research Center’s Project for Excellence in Journalism, more than 20 million tweets were sent about Hurricane Sandy in the span of 6 days.

The intelligent thing to do for your company just might be to explore social media intelligence.

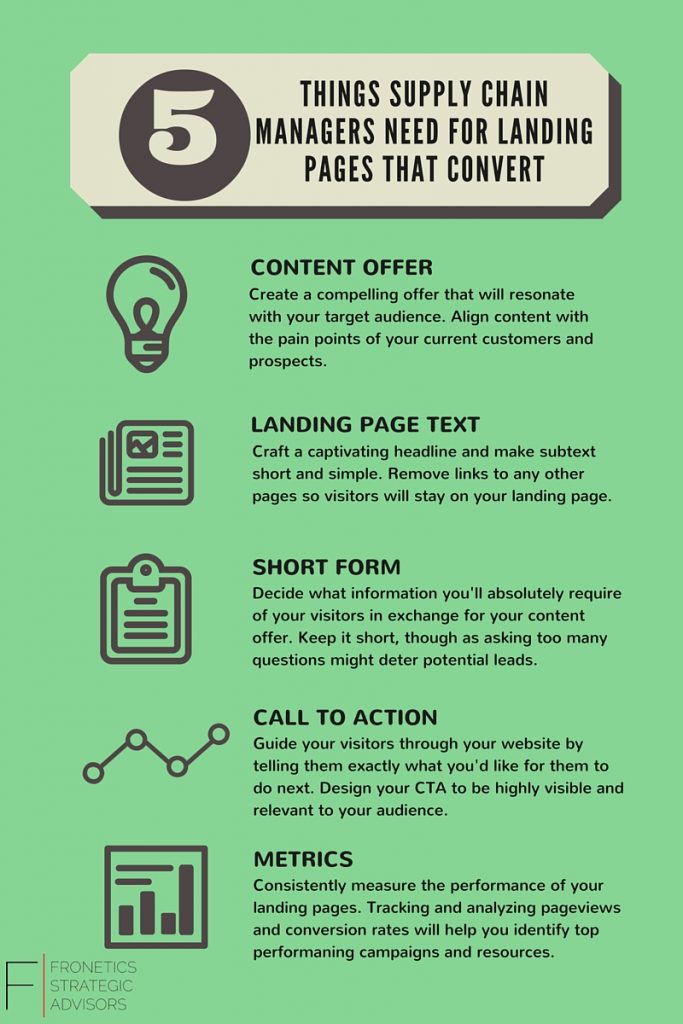

![5 Tips Supply Chain Managers Need to Build Landing Pages That Convert [Infographic]](https://www.fronetics.com/wp-content/uploads/2024/10/landing-pages-that-convert.jpg)

by Fronetics | Sep 28, 2015 | Blog, Logistics, Marketing, Supply Chain, Talent

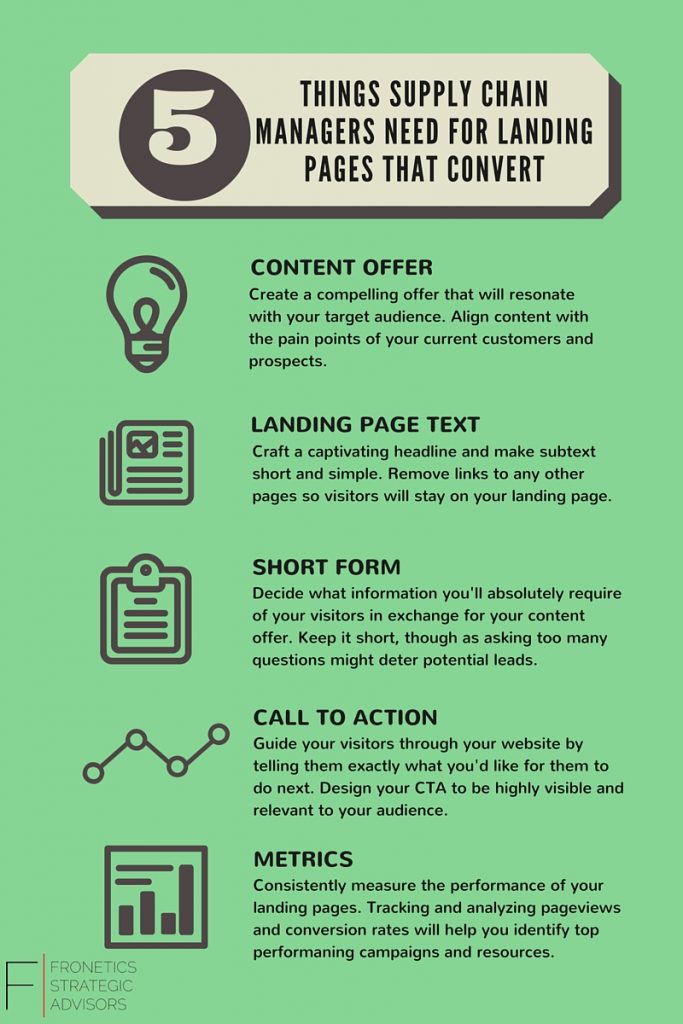

Landing pages are a fundamental tool in converting website visitors into leads. They’re what convince your visitors that they absolutely must download your fabulous resource offer. Yet often times they’re treated as the annoying little sibling to high-value content pieces – tagging along almost as if an after-thought. In reality, landing pages have just as much, and possibly even more importance than the content offer. Besides, what good is your best resource if it’s landing page stinks?

Here are five tips supply chain managers need to build landing pages that are sure to convert visitors into leads.

by Fronetics | Sep 24, 2015 | Blog, Content Marketing, Marketing, Strategy

Outsourcing isn’t new to the business world. It goes back as far as the Industrial Revolution. Before then, it was common practice for businesses to perform all functions of product and service delivery, from product manufacturing through to product delivery. Sometime in the mid-1800s, independent architects, engineers, and legal professionals began to operate in larger U.S. cities taking on project-based work for a number of clients.

More than a hundred and fifty years later, outsourcing has become a staple business tool, offering benefits for employees and employers alike. Employers enjoy a reduction (or cost savings) in operating costs, improve their focus on core competencies, and employees are free to concentrate on their highest and best use.

With tech now advancing faster than ever, your business should be looking to leverage outsource partners to support your digital efforts.

Here are our picks for 6 digital and content marketing tasks you should consider outsourcing:

1. Strategy

A 2014 study of B2B marketers found that companies who have a documented content strategy in place are more likely to consider their efforts to be effective than companies who do not have a documented strategy in place (60 percent vs. 11 percent).

Identify an outsource partner that can deliver a content strategy that is aligned with your business goals and objectives and one that is results driven.

2. Content creation

Effective content is not only aligned with your business goals and objectives, it is also quality content. Finding an outsource partner that excels at content creation drive profitable customer action. When it comes to finding the right outsource partner, put a premium on quality content, and remember the adage: you get what you pay for.

3. Social media

It’s important to recognize social media as the important business tool it is. As such, you should draw on the expertise of a social media outsourcing partner. These firms know what works and what doesn’t because they’re active every day on multiple platforms managing accounts for multiple clients. And it’s not just posting every now and then. A good social media partner will craft and publish great original content, but they’ll also curate great content from relevant sources, like industry partners. Outsourcing these tasks to the pros helps build a strong following and brand awareness for your company.

4. Web development and design

Because your company’s website is the primary digital tool of communication with customers and prospects, it literally pays to have web design and development functions performed by a knowledgeable professional. Hosting that capability in-house can be costly, though. Besides saving you thousands on employee compensation, outsource partners can often bring with them niche specialties, for instance, something like usability engineering isn’t something you would necessarily get from an in-house generalist.

5. eCommerce

Focus on your core product offerings rather than investing time, money, and resources into building and maintaining an eCommerce platform. Because it receives and stores sensitive information, eCommerce platforms need to be constantly updated and secured. Couple that with product line changes, future business growth, and changing platform needs, and it quickly becomes a full-time job that comes with a hefty in-house expense.

6. Projects that are outside your scope of expertise

It’s possible that projects will come up that require a skill set, like graphic design, which lies outside your company’s range of expertise. It’s far better to find a partner with this expertise rather than try to create an on-demand capacity to provide the service. Your clients will benefit from stellar work performed by a knowledgeable practitioner and you’ll enjoy cost savings by not committing to a long-term employee salary.

You may also like:

When it comes to marketing we work with our clients to create and execute strategies that drive success and elevate their brand position within the industry. Unlike other firms, we align marketing programs with business objectives and, through a data driven approach, are able to deliver results with a targeted ROI. Our team is comprised of strategists, marketing professionals, writers, designers, and experts in social media. Together we leverage our experience to increase brand awareness, position our clients as thought leaders, drive meaningful engagement with prospects and customers, and help businesses grow.

by Fronetics | Sep 23, 2015 | Blog, Logistics, Strategy, Supply Chain

Logistics is logistics is logistics– right? Wrong. The direction the product is moving in the supply chain – forward or backward – makes a difference.

Forward logistics, or the forward supply chain, is all about getting the product to market. In contrast, reverse logistics, or the aftermarket supply chain, is inclusive of events that move the product at least one step back in the supply chain. That is, reverse logistics is inclusive of activities that move goods from the consumer to the distributor or the manufacturer, and is inclusive of operations related to the reuse of products and materials.

The direction in which the product is moving matters. Companies that attempt to employ the same strategy for their reverse logistics process as they do for their forward logistics process do so at their peril.

The forward supply chain has its challenges. The forward supply chain has risks and it has surprises. However, the forward supply chain is more predictable and more certain than the aftermarket supply chain.

There is a greater level of uncertainty and predictability in reverse logistics. Because of this, when it comes to reverse logistics, flexibility needs to be a key component of your strategy.

Specifically, in forward logistics the product itself, the quality of the product, and the volume of the product are known and are relatively easy to forecast. Likewise, rules and regulations are fairly straightforward and uniform, and the value of the product is known.

When it comes to reverse logistics there are many unknowns. The product, the volume of the product, the quality of the product, and the value of the product are difficult to forecast. Rules, regulations, and restrictions are constantly evolving and vary by state, country and region. Moreover, the visibility and speed at which it is necessary for the aftermarket supply chain to move is vastly different than that of the forward supply chain.

It is important to remember that when it comes to the supply chain one size does not fit all. Incorporating flexibility into your aftermarket supply chain strategy is essential to your success.

This post originally appeared on Electronics Purchasing Strategies.

by Fronetics | Sep 22, 2015 | Blog, Logistics, Strategy, Supply Chain

The perception of the reverse logistics industry has shifted over the last several years. Reverse logistics has gone from being viewed as an afterthought to a necessary evil to being recognized as a wealth of opportunity. This shift has occurred as a result of several factors including: shortened product lifecycles, increased regulations and standards, consumer demand for corporate responsibility, and an increase in razor-thin margins. Equally important in the industry’s makeover – companies have come to understand and to realize the benefits of reverse logistics such as a reduction in costs, a revenue stream, and as a way to enhance customer loyalty.

Unfortunately when choosing a solutions provider, many companies fall prey to the assumption that a certain level of compliance and data security are givens. More often than not; however, the reality is that the service provider does not offer the level of compliance or data security assumed by the customer – and more often than not, the level that is offered by the service provider is inadequate. When due diligence is left to assumptions companies pay dearly.

Specifically, faulty assumptions regarding certain levels of compliance and data security provided via a service provider leave the customer open to lawsuits and fines as a result of non-compliance and leave the door open for data leakage and theft. The financial costs associated can be astronomical. Moreover, the company and the brand can take a significant hit resulting in a decline or even loss of customers and customer loyalty. In short, choosing a reverse logistics service provider that does not offer the compliance and data security necessary for your company can negate any gains realized as a result of your company’s reverse logistics strategy.

When selecting a reverse logistics service provider don’t make assumptions; don’t take the route of complacency. Instead, ask questions, conduct due diligence, and make sure that the level of service provided goes beyond meeting your needs – the service provider should be able to exceed your company’s needs.

When selecting a reverse logistics service provider, look for a provider who has network and standards in place which ensure global success. What does this look like? Arrow Value Recovery is the gold standard. Arrow provides uniform standards and quality controls. Unlike some service providers who default to the lowest common denominator, Arrow providers customers with consistent levels of service –globally. Moreover, Arrow ensures that every step of the recovery, data sanitization, and reuse and recycling process is not only transparent but is also 100 percent auditable.

Taking the time to thoroughly vet a reverse logistics service provider is essential. Don’t make assumptions and don’t default to complacency. Did you know that an estimated 70 percent of data breaches come from computers that are offline – typically computers that have been disposed of by the equipment owner? Don’t assume that your reverse logistics provider is offering your company the level of compliance and data security necessary – verify the facts.

This post was originally published on Electronics Purchasing Strategies.

![5 Tips Supply Chain Managers Need to Build Landing Pages That Convert [Infographic]](https://www.fronetics.com/wp-content/uploads/2024/10/landing-pages-that-convert.jpg)