by Fronetics | Dec 18, 2014 | Blog, Marketing, Social Media, Strategy

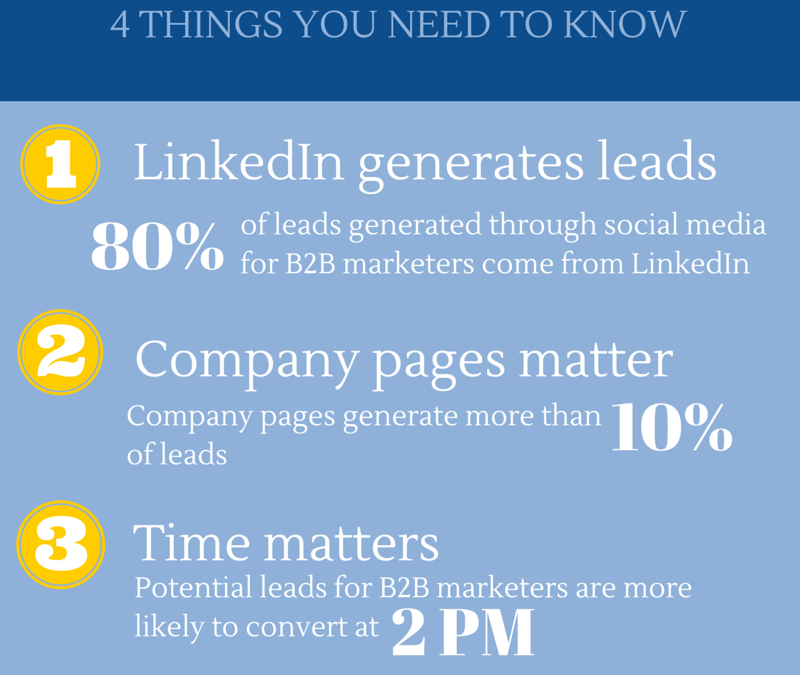

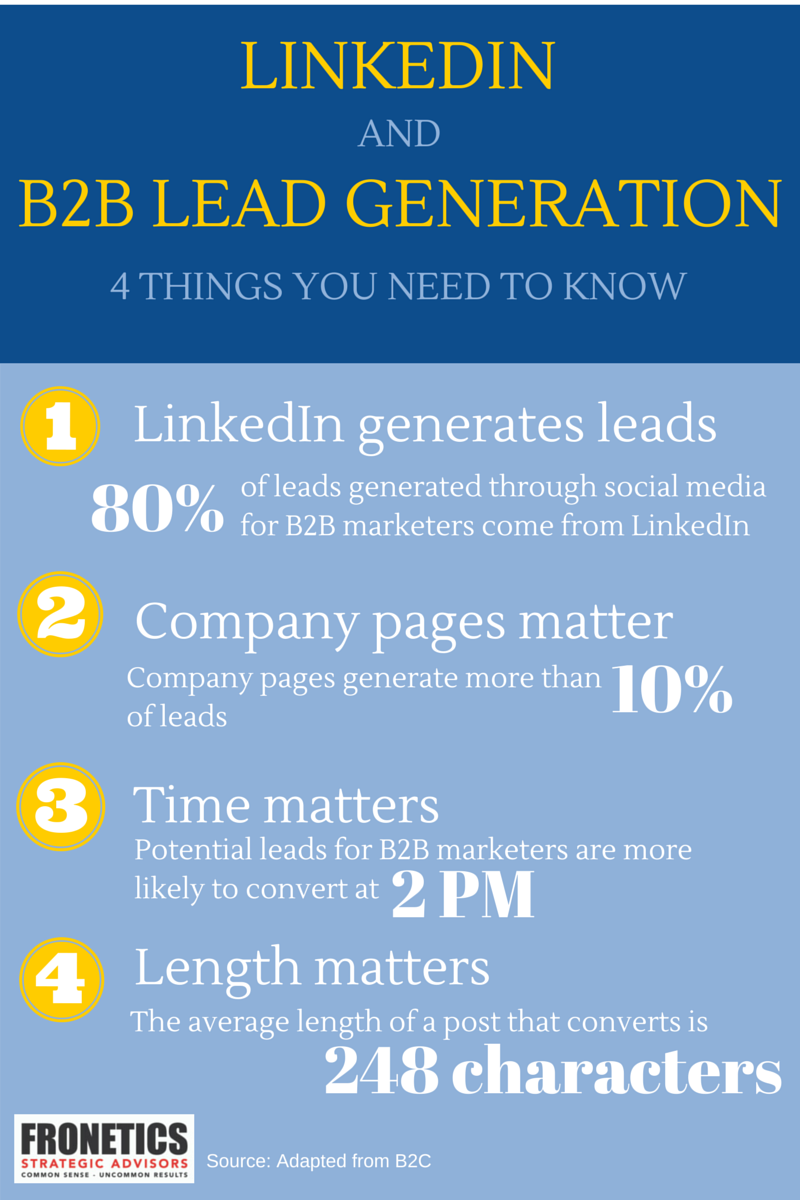

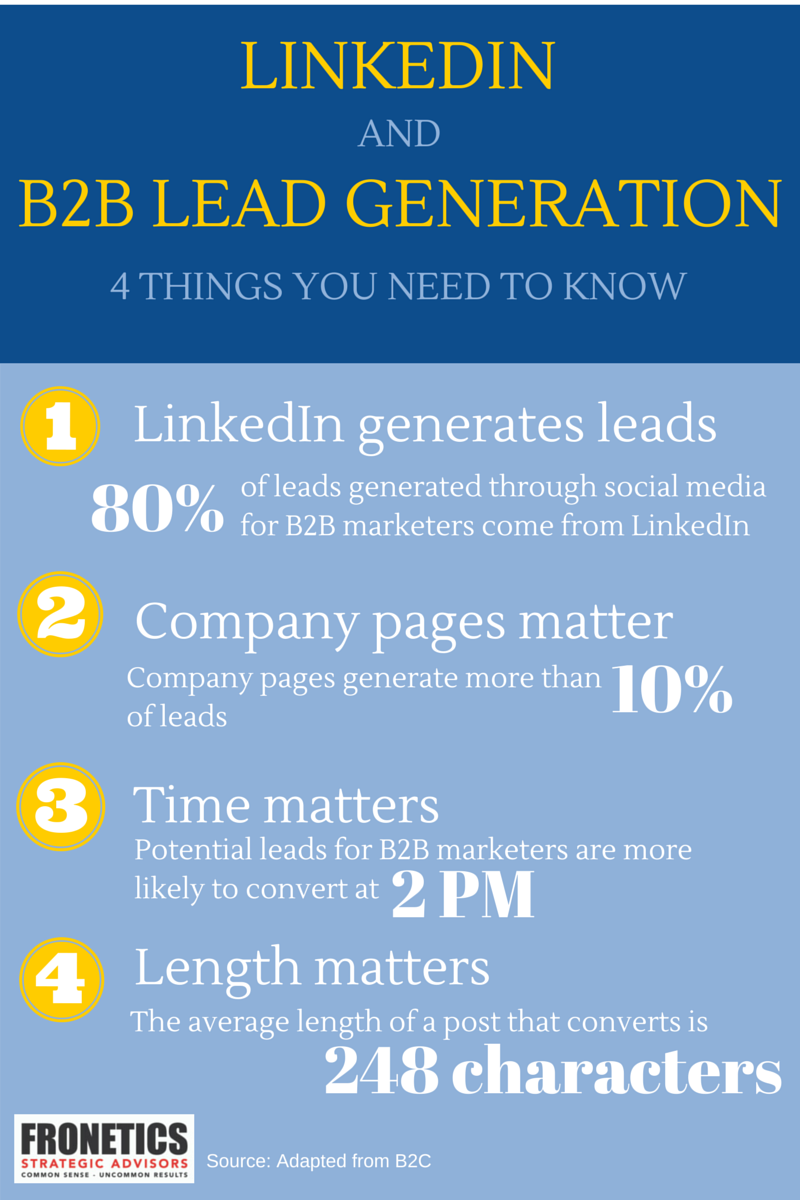

Oktopost, a social media marketing platform, analyzed over 100,000 posts on four different social networks (LinkedIn, Twitter, Facebook, and Google+) and found that LinkedIn is the most effective social network for B2B.

Oktopost found that more than 80% of B2B leads were generated through LinkedIn. Lead generation through other social networks paled in comparison:

- Twitter: 12.73%

- Facebook: 6.73%

- Google+: 0.21%

We’ve put together an infographic that outlines four things you need to know about LinkedIn and lead generation.

by Fronetics | Dec 17, 2014 | Big Data, Blog, Data/Analytics, Internet of Things

The Internet of Things (IoT) is ubiquitous. Because of this it can seem abstruse. Puneet Mehta does a great job of putting the concept in layman’s terms: “[A] plethora of “dumb” objects becom[ing] connected, sending signals to each other and alerts to our phones, and creating mounds of “little data” on all of us that will make marketers salivate.”

The mounds of data created by the advent of the IoT does not just make marketers salivate. Gartner predicts that the IoT will add $1.9 trillion in value to the economy by 2020. Looking ahead, Cisco estimates that the IoT will create over $14 trillion in value over the next 10 years.

In 2003 there were 500 million connected devices. Cisco estimates that this number will increase to 50 billion by 2020. Morgan Stanley believes this number will be higher – it estimates there will be 75 billion IoT devices by 2020.

“Dumb” objects are becoming connected; the physical and digital worlds are converging. Mounds of data are being collected.

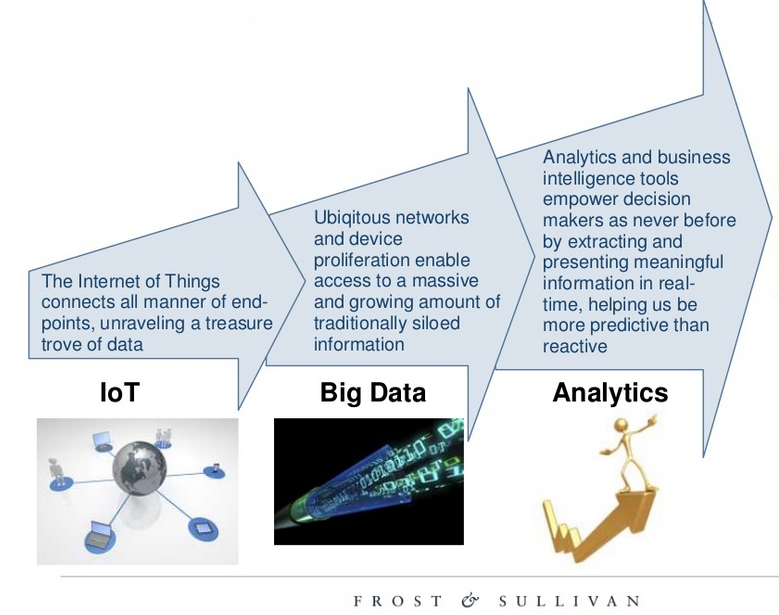

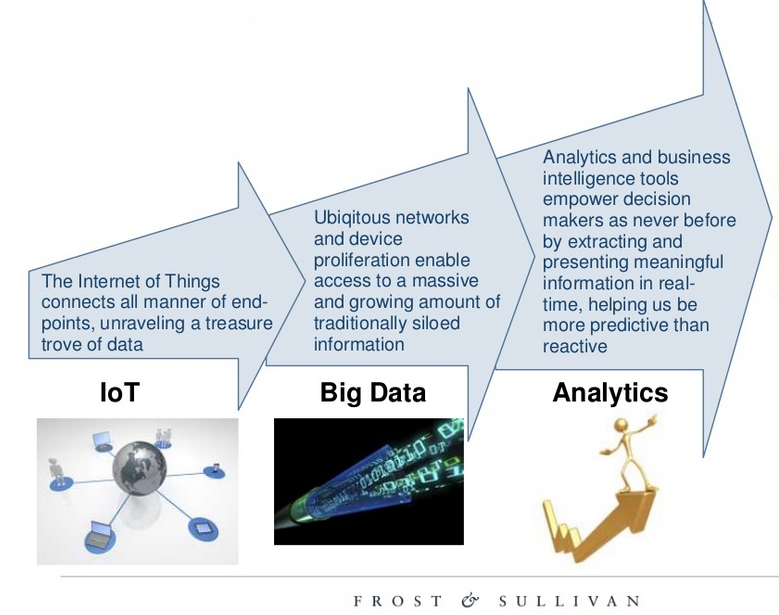

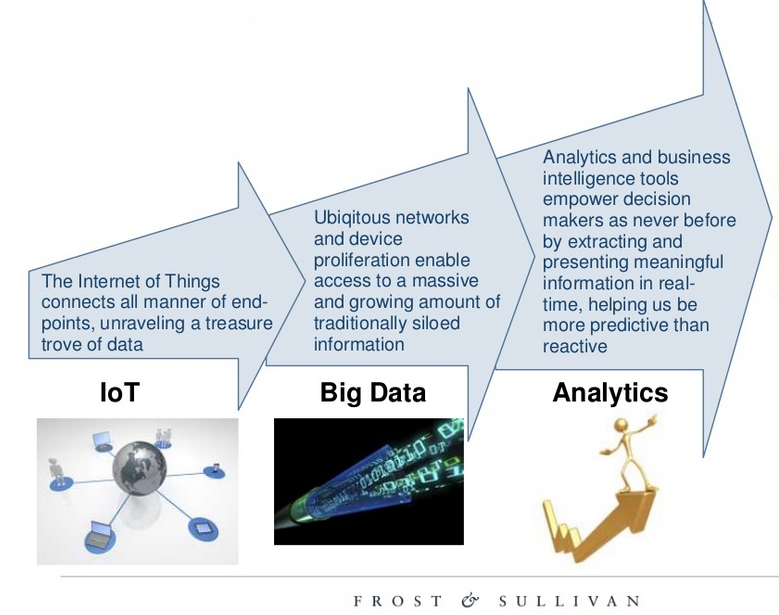

IoT and Big Data

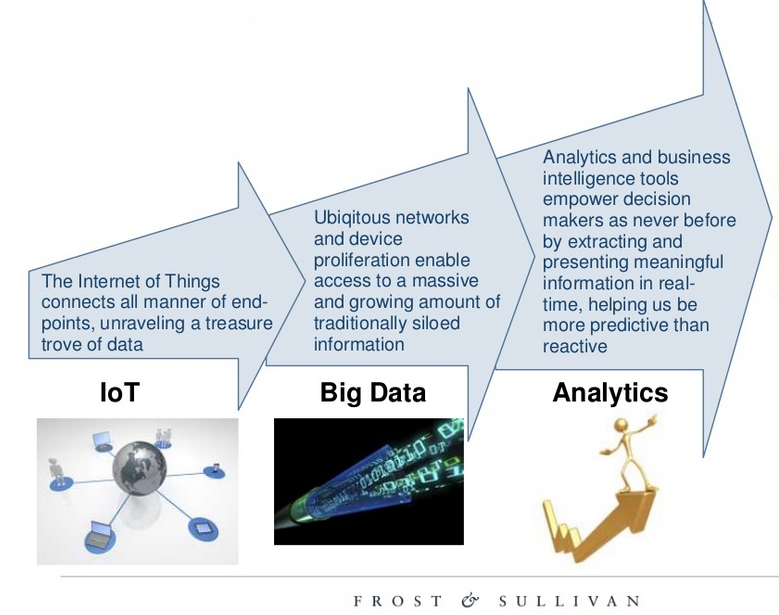

Mukul Krishna, from Frost & Sullivan, presented a simple incremental view of the relationship between the IoT and big data. In short, IoT devices can be thought of as data sources. These data sources generate an incredible amount of data – much of which was previously not accessible. The information and insights from big data allow for better decision-making.

The amount of big data created each day in 2012 was 2.5 exabytes (2.5×1018). In 2014 the amount of data were created each day was 2.3 zettabytes (2.3×1021),

An IDC forecast shows that the Big Data technology and services market will grow at a 27% compound annual growth rate (CAGR) to $32.4 billion through 2017 – or at about six times the growth rate of the overall information and communication technology market.

The need for a plan

McKinsey & Company offer sage advice: put a plan in place.

The payoff from joining the big-data and advanced-analytics management revolution is no longer in doubt. The tally of successful case studies continues to build, reinforcing broader research suggesting that when companies inject data and analytics deep into their operations, they can deliver productivity and profit gains that are 5 to 6 percent higher than those of the competition. The promised land of new data-driven businesses, greater transparency into how operations actually work, better predictions, and faster testing is alluring indeed.

But that doesn’t make it any easier to get from here to there.

So how does one get from here to there?

The answer, simply put, is to develop a plan. Literally. It may sound obvious, but in our experience, the missing step for most companies is spending the time required to create a simple plan for how data, analytics, frontline tools, and people come together to create business value. The power of a plan is that it provides a common language allowing senior executives, technology professionals, data scientists, and managers to discuss where the greatest returns will come from and, more important, to select the two or three places to get started.

What impact has the IoT and big data had on your company? Does your company have a plan in place?

by Fronetics | Dec 17, 2014 | Big Data, Blog, Data/Analytics, Internet of Things

The Internet of Things (IoT) is ubiquitous. Because of this it can seem abstruse. Puneet Mehta does a great job of putting the concept in layman’s terms: “[A] plethora of “dumb” objects becom[ing] connected, sending signals to each other and alerts to our phones, and creating mounds of “little data” on all of us that will make marketers salivate.”

The mounds of data created by the advent of the IoT does not just make marketers salivate. Gartner predicts that the IoT will add $1.9 trillion in value to the economy by 2020. Looking ahead, Cisco estimates that the IoT will create over $14 trillion in value over the next 10 years.

In 2003 there were 500 million connected devices. Cisco estimates that this number will increase to 50 billion by 2020. Morgan Stanley believes this number will be higher – it estimates there will be 75 billion IoT devices by 2020.

“Dumb” objects are becoming connected; the physical and digital worlds are converging. Mounds of data are being collected.

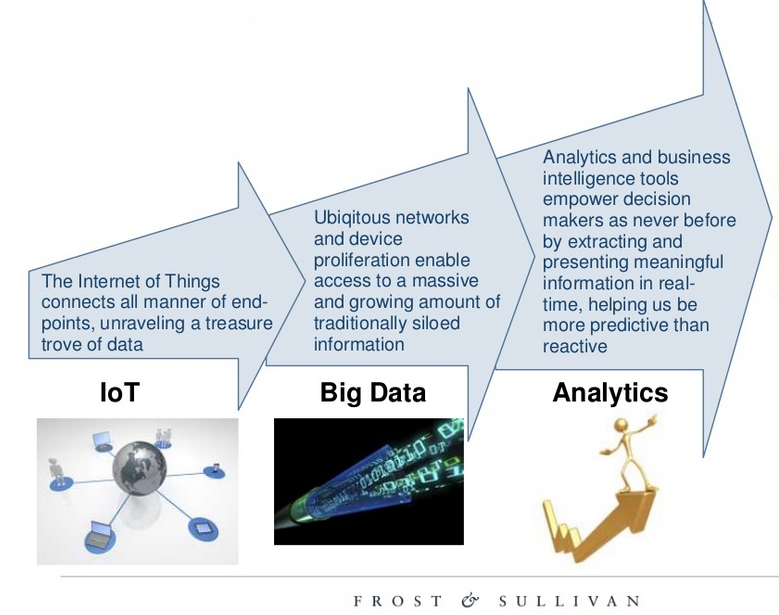

IoT and Big Data

Mukul Krishna, from Frost & Sullivan, presented a simple incremental view of the relationship between the IoT and big data. In short, IoT devices can be thought of as data sources. These data sources generate an incredible amount of data – much of which was previously not accessible. The information and insights from big data allow for better decision-making.

The amount of big data created each day in 2012 was 2.5 exabytes (2.5×1018). In 2014 the amount of data were created each day was 2.3 zettabytes (2.3×1021),

An IDC forecast shows that the Big Data technology and services market will grow at a 27% compound annual growth rate (CAGR) to $32.4 billion through 2017 – or at about six times the growth rate of the overall information and communication technology market.

The need for a plan

McKinsey & Company offer sage advice: put a plan in place.

The payoff from joining the big-data and advanced-analytics management revolution is no longer in doubt. The tally of successful case studies continues to build, reinforcing broader research suggesting that when companies inject data and analytics deep into their operations, they can deliver productivity and profit gains that are 5 to 6 percent higher than those of the competition. The promised land of new data-driven businesses, greater transparency into how operations actually work, better predictions, and faster testing is alluring indeed.

But that doesn’t make it any easier to get from here to there.

So how does one get from here to there?

The answer, simply put, is to develop a plan. Literally. It may sound obvious, but in our experience, the missing step for most companies is spending the time required to create a simple plan for how data, analytics, frontline tools, and people come together to create business value. The power of a plan is that it provides a common language allowing senior executives, technology professionals, data scientists, and managers to discuss where the greatest returns will come from and, more important, to select the two or three places to get started.

What impact has the IoT and big data had on your company? Does your company have a plan in place?

by Fronetics | Dec 16, 2014 | Blog, Supply Chain

Is your distribution center proving to be a cost center? Looking to increase profits while reducing cost? Here’s how you can transform your distribution center into a profit center.

Synchronize

Anemic communication and fractured messaging within and across departments can be very costly. Build a culture in which exceptional communication in and between departments is a central component. Establishing clearly defined expectations and promoting openness will benefit your employees and your bottom line.

Optimize space

Take advantage of your distribution center. Every single inch should be used in a strategic manner. Empty or poorly used space will quickly transform your distribution into a cost center. Inspect your distribution center with a fine-toothed comb and a healthy dose of honesty. Identify obsolete inventory and work to eliminate it. Inventory that’s not necessarily obsolete, but might not be ideal for your company, should be matched with channels that will generate revenue for these products. Ensuring the optimization of space by eliminating unused and/or outdated inventory will play a significant role in turning your distribution center into a profit center.

Embrace technology

While the cost of purchasing technology may seem insurmountable, often the cost of not adopting specific technologies is even greater. Technology can serve to increase productivity, reduce error, and improve safety. Your customers will notice and appreciate it, too.

Invest in your employees

Attract excellent employees and cultivate them. Be willing to devote time and resources to your employees. Employee turnover is expensive. The cost of replacing an employee can range from 50 to 400% of their annual salary; it will serve you well to create an environment in which your employees want to stay.

Be flexible

Flexibility isn’t just essential to growth, it’s one of the vital elements to ensuring efficient day-to-day operations of your distribution center. When your distribution center is equipped to be able to process a wide variety of goods and SKUs, your distribution is more likely to be a profit center than a distribution center, which can process only a limited number of SKUs.

Scrutinizing every aspect of your distribution processes – from the buildings to what’s in them, and from the workers to how they work – will prove to be worth the investment of time and effort as all your hard work begins to pay off, and pay out.

Let us know what strategies have worked for you.

by Fronetics | Dec 16, 2014 | Blog, Supply Chain

Is your distribution center proving to be a cost center? Looking to increase profits while reducing cost? Here’s how you can transform your distribution center into a profit center.

Synchronize

Anemic communication and fractured messaging within and across departments can be very costly. Build a culture in which exceptional communication in and between departments is a central component. Establishing clearly defined expectations and promoting openness will benefit your employees and your bottom line.

Optimize space

Take advantage of your distribution center. Every single inch should be used in a strategic manner. Empty or poorly used space will quickly transform your distribution into a cost center. Inspect your distribution center with a fine-toothed comb and a healthy dose of honesty. Identify obsolete inventory and work to eliminate it. Inventory that’s not necessarily obsolete, but might not be ideal for your company, should be matched with channels that will generate revenue for these products. Ensuring the optimization of space by eliminating unused and/or outdated inventory will play a significant role in turning your distribution center into a profit center.

Embrace technology

While the cost of purchasing technology may seem insurmountable, often the cost of not adopting specific technologies is even greater. Technology can serve to increase productivity, reduce error, and improve safety. Your customers will notice and appreciate it, too.

Invest in your employees

Attract excellent employees and cultivate them. Be willing to devote time and resources to your employees. Employee turnover is expensive. The cost of replacing an employee can range from 50 to 400% of their annual salary; it will serve you well to create an environment in which your employees want to stay.

Be flexible

Flexibility isn’t just essential to growth, it’s one of the vital elements to ensuring efficient day-to-day operations of your distribution center. When your distribution center is equipped to be able to process a wide variety of goods and SKUs, your distribution is more likely to be a profit center than a distribution center, which can process only a limited number of SKUs.

Scrutinizing every aspect of your distribution processes – from the buildings to what’s in them, and from the workers to how they work – will prove to be worth the investment of time and effort as all your hard work begins to pay off, and pay out.

Let us know what strategies have worked for you.

by Jennifer Hart Yim | Dec 11, 2014 | Blog, Supply Chain

Note: This is a guest post written by Barbara Jorgensen, managing editor, Electronics Purchasing Strategies.

Barb has more than 20 years’ experience as a journalist, working for leading electronics industry publications such as Electronic Business, Electronic Buyers’ News and EDN. As a freelance writer, Barb wrote and managed an award-winning custom publication for Sager Electronics; was a leading contributor to Avnet Global Perspectives magazine; was a regular columnist for the National Electronics Distributors Association monthly newsletter and wrote for industry associations such as IPC. Barb was also a featured blogger on the B2B Website Allbusiness.com and helped launch Electronics Sourcing North America, a start-up magazine serving purchasing professionals in the Americas.

Prior to her freelance career, Barb was a senior editor at Electronic Business, the pre-eminent management magazine for the electronics industry, featuring world-class manufacturing companies such as Dell, Hewlett-Packard, Cisco and Flextronics International. Before joining EB for the second time, Barb spent 6 years with Electronic Buyers’ News as managing editor, distribution, winning several awards for coverage of the distribution beat. A graduate of the University of Binghamton, Barb began her journalism career with the Gannett newspaper chain. She has worked for a number of local newspapers in the Greater Boston area and trade journal publishers Reed Business Information and UBM.

Barb can be reached at [email protected].

Why supply and demand remain unbalanced, even in the connected world

With the advent of the internet and social media, it would seem that the supply chain has more opportunity than ever to collect and disseminate information. In the electronics industry, component makers, distributors and OEMs communicate in traditional ways: EDI, Excel, the internet, extranets, MRP/ERP systems and good old-fashioned e-mail; along with cloud-based platforms, Twitter, Facebook and other social media. It’s impossible to NOT be connected.

Yet, component suppliers and contract manufacturers say that that OEMs’ ability to forecast is worse than it has ever been. OEMs still can’t predict their customers’ demand. Component suppliers—many of which have a minimum of 16-week lead times for production – often end up with too much product. Distributors pick up the slack, but as soon as inventory starts to build in the channel alarm bells go off. With so many opportunities for communication, how is this possible?

There are a couple of industry dynamics that could explain this. First, it’s been at least a decade since the electronics industry has seen any kind of significant shortage. Spot shortages cropped up following the Japan tsunami and Thailand floods of 2011, but nothing that could be termed industry-wide. Buyers have become accustomed to getting what they want when they want it. Moreover, the internet has made inventory and pricing information available to anyone with a search engine. Components appear to be available 24/7, 365 days a year. The urgency to forecast has diminished.

Then there is lean, just-in-time and build-to-order. All of these practices have effectively shortened the time between order and fulfillment. In practice, OEMs are working with an actual order – not a forecast – and the correct number of components is stored nearby. Lean has diminished the levels of inventory in the pipeline, so as long as everything is flowing as planned, there shouldn’t be any surprises.

Finally, the supply chain has figured out that it has to be more responsive and nimble regarding last-minute changes. In order to respond to JIT and BTO, inventories have to be maintained closer to manufacturing sites. Instead of single mega-hubs, suppliers and distributors have warehousing in key regions of the globe, and utilize third-party logistics when necessary. The ability to respond within 24 hours is a reality in most parts of the world.

So why are supply and demand in a state of perpetual imbalance? It’s not a dearth of data. Partners don’t necessarily trust the information they receive. Distributors routinely compare customer forecasts to historic orders to see if something is out of whack. Certain types of information are still withheld from partners: OEMs don’t share their preferred-pricing agreements with EMS. Online inventory is treated with a grain of salt: depending on how often data is refreshed, parts may or may not available at the price at which they are listed. Social media seems to be best used during disasters and for taking the pulse of market—what is trending and what is not.

Not sharing certain types of information is considered strategic by companies in the supply chain; and double-checking forecasts is a responsible business practice. However, these practices mean the supply chain may never be transparent. Information may be more available than ever, but visibility of data is an entirely different matter. Yet, even lack of information is no longer a problem in the supply chain, but full visibility remains elusive.