by Fronetics | Jul 1, 2015 | Blog, Leadership, Strategy

How to increase prices and retain customers

How to increase prices and retain customers

Companies raise prices all the time. There are various reasons, explanations, and results. Sometimes companies disclose the changes, but sometimes customers and clients never even catch wind of a change. Let’s have a look at the causes, the perception, and the actions to take.

Why?

Usually there’s an impetus for a company to raise prices. Perhaps there’s a business model already in place to raise future prices, but often a price increase is tied to another event. Here are some typical reasons:

Spike in raw material prices used in manufacturing products

Is there dearth of raw materials used to make the products your company is producing? Perhaps there’s a lack of access to the materials due to stalled transportation from inclement weather, natural disaster, drought, etc. Perhaps resources are dwindling or other roadblocks in the supply chain are driving up prices.

Services or products have become incredibly popular (value-based pricing)

Perhaps you realize that your services or products weren’t appropriately priced early on, and you’re realizing your product’s value in the market. You may also need to reduce demand for some time by increasing prices.

Unexpected change in business or a new tact

Perhaps you’ve lost business recently or your business strategy has changed and you need to cover costs by increasing prices. These changes can come with the opening of a new branch or factory, or the launch of new services or products.

Inflation and market trends

It would be nice to keep prices where they started 5, 10, or 20 years ago, but most businesses aren’t sustainable that way. As all prices of other goods and services rise, so too must yours.

Perception

As detailed in an article about the power or perception, behavioral economist Richard Thaler ran an experiment in which some study members were asked how much money they would give a friend to go buy beer at a “run-down grocery store”. Some study members were asked to get the alcohol at a “fancy hotel”. According to the article, “the fancy resort’s median price was 71% higher than the run-down store’s price.”

This might suggest that considering the perception of your product or services could be key to your next price adjustment. Considering what your current branding is, who your competitors are, and where you want to see your company could help shift your own perception of your company, and that of others. Aligning the two could be critical to successfully stewarding a price shift.

How?

It’s important thoroughly think through a price adjustment. Considering your own worth is important, but understanding that some clients and customers won’t be convinced can be a hard pill to swallow. To make the change more palatable, or even attractive, you should consider these options:

Consider the tactic (good-value pricing, value-added pricing)

Are you planning on going to offer any promotions or price discounts in the future? Are you going to attach value-added features and services to support the higher prices? Are you considering doing bundles packages? It’s important to answer theses questions so that you can communicate to clients and customers.

Consider timing

Have you recently increased prices? Does it feel too soon to do it again? You could risk loyalty from consumers and clients if price increases come back to back. However some believe that small increases frequently are better than large increases infrequently.

Are you implementing new, improved services or bundling new packages? An announcement tied to value increase or product change can be more comfortable for consumers and clients.

Make a solid announcement

Most people feel it is best to announce an increase, especially to current customers and channel partners, rather than try to hide the increase. People don’t want to feel fooled or ignored. They want transparency.

Understand that wording is critical

Being direct and confident in expressing the increase is the best tact. Remember that if you value your product and services, your customers and clients are more likely to as well.

Although you’re briefly sharing the reason for the increase, don’t feel the need to disclose sensitive financial information.

Lastly, provide clear timing on the changes and be sure that changes don’t violate any pre-existing agreements.

Although some customers and clients may bristle at an increase of prices, if you’ve been playing fairly and providing solid products and services, many loyal customers will come along for the ride. If you value yourself, and others value you, you can survive a price increase. You may even thrive from one.

Fronetics Strategic Advisors is a leading management consulting firm. Our firm works with companies to identify and execute strategies for growth and value creation.

Whether it is a wholesale food distributor seeking guidance on how to define and execute corporate strategy; a telematics firm needing high quality content on a consistent basis; a real estate firm looking for a marketing partner; or a supply chain firm in need of interim management, our clients rely on Fronetics to help them navigate through critical junctures, meet their toughest challenges, and take advantage of opportunities. We deliver high-impact results.

We advise and work with companies on their most critical issues and opportunities: strategy, marketing, organization, talent acquisition, performance management, and M&A support.

We have deep expertise and a proven track record in a broad range of industries including: supply chain, real estate, software, and logistics.

by Fronetics | Jun 23, 2015 | Blog, Logistics, Marketing, Social Media, Strategy, Supply Chain, Transportation & Trucking

Drew McElroy, founder of the start-up Transfix, is no newcomer to the trucking industry. McElroy was born into the business; his parents owned and operated the freight brokerage Andrew’s Express, affectionately naming it after McElroy.

“I remember listening to my father structure deals. As a kid, it was all utterly confusing to me,” recalls McElroy. “I finally started to get my head around the economics of the business in my teens. From that point on, I became increasingly aware of the industry’s inefficiencies.”

Not long after McElroy graduated college, his father passed away unexpectedly. McElroy, already working for the family business, took over as president. In that time, McElroy successfully increased annual revenues from $4 million to $12 million. While impressive, McElroy still struggled with how the industry traditionally operated. “It was clear that our family business wouldn’t be the platform for world domination,” laughs McElroy. “But I believed that, fundamentally, there was a better way to get things done.”

Determined to build a new foundation based on his belief in “a better way,” McElroy left the family business and set out for San Francisco. He would spend the next year and a half couch surfing and networking in order to gain the expert business and tech insight he needed to plan what would become Transfix. “I knew logistics and I knew trucking, but I knew nothing about venture capital, or how to move from idea to implementation,” says McElroy. “I decided I should try – and try big. If I fail, I fail, but at least I tried.”

In 2013, McElroy was introduced to Jonathan Salama. Salama was among Gilt’s early engineers, and was pivotal in building the flash sale giant’s infrastructure and inventory software. McElroy knew Salama would be key in taking his idea to the next level; Transfix had claimed its co-founders, and its recipe for industry-leading success.

Transfix is a fully automated marketplace that is all about getting things from one place to another. What sets Transfix apart is the company’s platform and approach is vastly more efficient than the traditional approach, and it is much more user-friendly.

Transfix takes the industry’s inefficiencies head on. Transfix is a digital on-demand freight marketplace. It provides industry-leading mobile technologies and location-based jobs offers for independent over-the-road truck drivers, as well as cloud-based management platforms for small carriers and shippers

Here’s how it works:

A customer logs into the Transfix TMS and enters a new shipment. The platform automatically identifies the best driver depending on location, size of truck, etc., sending a load offer alert to the driver or company dispatcher by mobile SMS message or email. The load is accepted by electronic signature, at which point the customer receives automatic notification and the driver becomes fully visible within the customer’s real-time dashboard. Load management from that point on becomes “as simple as Tinder.” Transfix geofences the driver with a five mile radius, immediately alerting Transfix of any issues. Once the load is delivered, the driver is paid within 24 to 48 hours, significantly faster than the industry standard.

Transfix just launched an app (iOS and Android) that is focused on truck drivers. Transfix’s app integrates with the company’s digital marketplace and is driver-centric. The app gives drivers the ability to manage loads, map their itinerary, and manage payments. The app also provides truck drivers with trip planning essentials including the location of showers, ATMs, weigh stations, fuel prices, and weather. The app is free and can be used by anyone with a valid motor carrier number – the driver does not have to associated with Transfix. “Developing this app and making it freely available to all drivers is just the right thing to do,” says McElroy. “Without drivers, this industry would not exist. We need to do right by drivers by making their lives easier.”

Things are moving fast for McElroy and Transfix. Within 15 minutes of updating his LinkedIn profile, McElroy got a call from a logistics Manager at Barnes & Noble and, before he hung up, had freight loads to manage. Fast forward a few months – with Transfix, Barnes & Noble has realized improvements in their processes and has seen their deadhead runs (times driving without cargo) cut by at least 50%.

Transfix has raised close to $2.5 million to date and is already generating several thousand a month in revenue.

McElroy and Transfix are poised for world domination – mind you, a win-win benevolent hegemony – a la Uber.

Fronetics Strategic Advisors is a leading management consulting firm. Our firm works with companies to identify and execute strategies for growth and value creation.

Whether it is a wholesale food distributor seeking guidance on how to define and execute corporate strategy; a telematics firm needing high quality content on a consistent basis; a real estate firm looking for a marketing partner; or a supply chain firm in need of interim management, our clients rely on Fronetics to help them navigate through critical junctures, meet their toughest challenges, and take advantage of opportunities. We deliver high-impact results.

We advise and work with companies on their most critical issues and opportunities: strategy, marketing, organization, talent acquisition, performance management, and M&A support.

We have deep expertise and a proven track record in a broad range of industries including: supply chain, real estate, software, and logistics.

by Jennifer Hart Yim | Jun 22, 2015 | Blog, Manufacturing & Distribution, Strategy, Supply Chain

This article is part of a series of articles written by MBA students and graduates from the University of New Hampshire Peter T. Paul College of Business and Economics.

Melanie Payeur graduated from the University of New Hampshire in 2007 with a degree in Mechanical Engineering. She has since worked in various roles supporting manufacturing and packaging operations in the food and beverage industry.

Do you know where your byproducts go?

Do you know where your byproducts go?

Manufacturing often produces some sort of physical byproduct. Examples range from plastic strapping on a pallet of corrugate boxes to carbon dioxide collected off a tank of fermenting beer. Byproducts are the unspoken of and often neglected “cousin” of manufacturing.

Byproducts of manufacturing can be compared to the stage crew at a Broadway show or on a Hollywood movie set. They serve an important purpose. Without the lights, cameras, and curtains, there is no show. Similarly, without plastic strapping, a pallet of corrugate would fall over during transport because it wasn’t properly secured.

The stars of the show are the finished goods on store shelves. Just like people don’t stick around to see the name of the on-set hair-stylist when the credits roll at a movie, consumers often don’t think about the byproducts associated with the packaged food they eat or other goods they purchase. It’s possible that they don’t even know these things exist.

However, consumers are becoming more conscious of supply chain issues. Many have an awareness what Fair Trade is in association with sourcing of products such as coffee and cocoa beans. They discuss agricultural sourcing and the ethical (or not) treatment of animals raised to be part of the food chain. Even the effects of emissions and chemical waste on the environment are among topics of which many consumers have some awareness.

Plastic old, Plastic new

What about the plastic strapping on that pallet of corrugate though? Where does it go? Who even knows it exists other than the operator that cuts it off the pallet in the factory? Could it become a plastic bottle someday? Or a swing set? Maybe it will become plastic strapping again?

While countless other types of byproducts exist, plastic is a particularly interesting example. Fluctuations in the price of petroleum are directly correlated to the price of brand new, non- recycled plastic pellets. It is completely possible, and often realistic, that it is less expensive to create brand new plastic strapping than it is to recycle old strapping.

Trailer Bags and Trash Bowls

Creative and novel uses of byproducts are happening today. One example is a Swiss company called Freitag who produces trendy messenger bags, wallets, and purses from old side panel tarps (popular on tractor trailers in Europe). At the end of their useful life on the road, these tarps are purchased by Freitag and sewn into functional accessories.

Another example specifically related to plastic are Garbage Bowls made famous by Food Network host, Rachael Ray. These bowls are made from recycled pieces of broken plates. There’s a byproduct in there somewhere!

While these are great examples of repurposing byproducts into something new, the truth is that Freitag was originally looking for a material that would create a durable and functional product. Lucky for them, reusing something that might have otherwise been thrown away is a great marketing story. They charge an average of $200 for a standard messenger bag. Is it realistic that the reverse situation can create profits? Can we find another use for production process byproducts which would create a trendy or otherwise highly desirable product?

Can we do better than throwing our byproducts away?

If it’s not a company’s core competency, it probably shouldn’t get into the business of designing handbags. However, as supply chain professionals, we should understand all of the byproducts of our manufacturing process; especially those related to materials that we source as inputs, like plastic strapping.

It is as important to look at the waste stream from our process as it is to examine how we source raw materials. Are we recycling our byproducts? Is there someone who is looking for our ‘trash’ as an input to their process? Do we have the opportunity to have a profitable side business as a coincidental supplier to someone else? At the very least, can we do better than throwing our byproducts away?

An example of success can be seen in the food manufacturing industry. Some companies donate or sell their byproducts to the Bakery Feeds Program. This organization creates animal feed out of food byproducts such as misshapen cupcakes and other edible process waste. It might be cost neutral to dispose of waste in this way, but that is better than otherwise paying for disposal.

I challenge you to examine the waste streams associated with your process. Identify where at least one of your byproducts could go. From here to there and there to here, your byproducts could end up anywhere.

by Fronetics | Jun 10, 2015 | Blog, Logistics, Marketing, Social Media, Strategy, Supply Chain

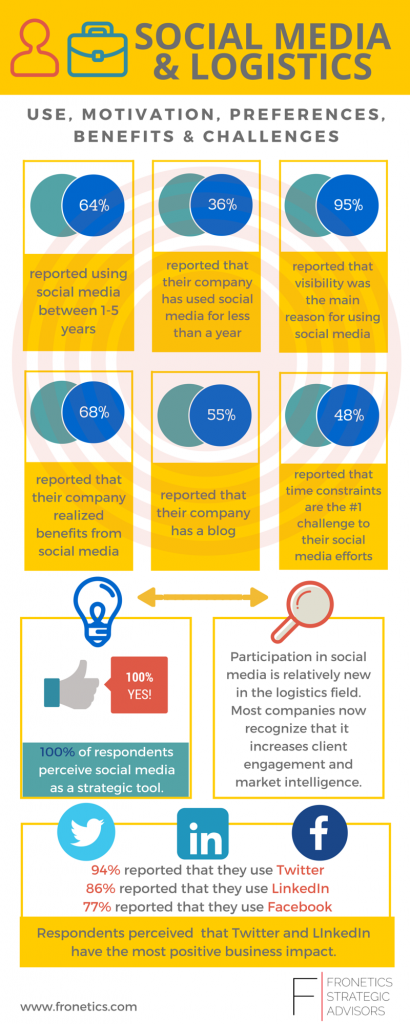

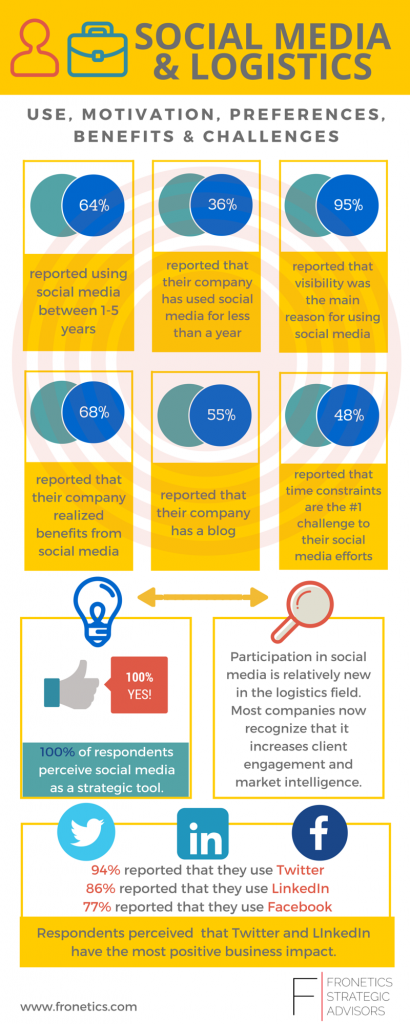

Fronetics Strategic Advisors conducted a survey focusing on social media and logistics and supply chain companies. Respondents shared information on their social media use, motivation, preferences, benefits, and challenges. One-hundred percent (100%) of respondents reported that they have used social media for five years or less, indicating that social media is a relatively new strategy for logistics and supply chain companies. Mirroring other industries, including those in Fortune 500 status, social media is playing an increasingly important role in company branding, marketing, and client engagement.

For the current state of social media and logistics, here is an infographic that summarizes many of the key points from the full report.

by Fronetics | May 27, 2015 | Blog, Strategy, Supply Chain, Talent

Mickey North Rizza talks women in the supply chain

Mickey North Rizza talks women in the supply chain

As part of our series on women in the supply chain, I spoke with Mickey North Rizza, VP, Strategic Services at BravoSolution. Mickey holds the distinction of Top Female Supply Chain Executive. She has 25 years of senior-level procurement, sourcing and supply management experience. Mickey has also been an award-winning Supply Chain analyst with Gartner and AMR Research.

How did you get your start in the supply chain industry? (Similarly, why did you choose the industry?)

This is a fun story for me. At Michigan State, I was a Delta Gamma helping out our Anchor Splash team. My mission was to find a television that a local company would donate to the winning Fraternity. And of course, it had to be the largest and best TV on the market for the day. So, I pulled out the yellow pages, started calling around and found a few companies that were willing to help but would not donate. I learned to negotiate pretty quickly. At that time my major was prelaw – and I was bored. I looked into Material’s Logistic Management – an older term for Supply Chain and chose this as my major with two concentrations – Purchasing and Operations. The rest is as they say, history. Thank goodness Purchasing has evolved, as negotiating is just a minute portion, but for this young adult it made all the difference.

How did you get to where you are today?

I put in long career hours, learning everything I could from so many. My thirst for knowledge is still vast and that keeps me going and enjoying what I do. I also had some great mentors and some not so good leaders and coworkers. All of these individuals have taught me lessons in the business world – good and bad. I firmly believe that everyone has something to teach us – we just need to listen, process and apply it. Sometimes we internalize the lessons we learn and others we let go – but all are learning experiences for ourselves. In the analyst world we called it triangulation – someone can always use the knowledge you have gained and they in turn can impart knowledge to you – though you must listen to learn.

My mentors were the CEOs, CFOs, CIOs, Division Presidents, CPOs, Supply Chain Leaders, Business Unit leads, General Managers, Editors, Analysts, Marketing and Sales professionals and, yes, even many of the suppliers and vendors I have worked closely with over the years. Each has given me a reason to pause and consider at a particular point in time and that has somehow enhanced my career.

Lastly, I have a strong, close immediate family. My grandparents and parents set a great work example early. My parents continue to be a source of inspiration for me. My sister is an amazing woman in Technology and Consulting and a constant source of ideas as I listen to her stories. My husband, while in a very different profession, is awesome – he listens, coaches and gives me strength to achieve even more than I did yesterday. And lastly, Delta Gamma has taught me to be the best I can be, all the time and in every way possible.

Who do you see as leaders (female) within the supply chain industry?

I have broken up the leaders in a few categories because I think it is helpful in terms of their leadership and current positions.

Marketing

- Andrea Brody, BravoSolution

- Christine Crandell, New Business Strategies

- Elaine Benfield, Ariba/SAP

- Allison Crawford, Supply Chain Insights

Analysts

- Lora Cecere, Supply Chain Insights

- Noha Tohamy, Gartner

- Dana Stiffler, Gartner

- Maggie Slowick, Procurement Leaders

Procurement

- Lisa Martin, Teva Pharmaceuticals

- Stephanie Sklar Financial Services

- Cynthia Dautrich, Kimberly Clark

- Cathy Herr, Eli Lilly

Risk

- Jessica Sanchez, CR Bard

- Rose Kelly-Falls, Rapid Ratings

- Edna Conway, Cisco Systems

Supply Chain

- Linda Santus Topping, Colgate

- Stacey Lallier, J&J

- Kate Vitasek, University of Tennessee

What opportunities do you see for women in the supply chain?

The opportunity is vast. As more and more companies outsource, the supply chains become more complex. The complexity means that great technology becomes even more critical to ensure proper visibility, actionable solutions and knowledge management. Rolling this all together requires the soft skills of managing relationships internally as well as externally with our partners, the industry and also to manage the messages to the market. While business has traditionally been a man’s world, more and more women are now in businesses. Most women by nature have been relationship builders. They encourage, collaborate and innovate with others for the best outcome. It is only natural that these tendencies gravitate to the business world and most importantly into Supply Chain.

Challenges?

The challenges for women remain the same – breaking into the man’s world. While many women have done it, to be really successful women need to utilize some of the components of Lean In! In addition, women must be comfortable staking a claim on their position, working from this position as a leader and a coworker so that the company can achieve it greatest results. In many cases I know I have worked just as hard if not more so than my male coworkers, but I have also come to appreciate the lessons these men have taught me – work smarter, not harder; give it your all and expect perfection; take risks – never be afraid to fail because it is in failure you learn your greatest lesson and can apply it in the future; and always believe in yourself.

A final thought here is that we all can’t be perfect, but we can expect the best, believe in the best, give our best and achieve excellence. But you have to DO IT!

Any advice for women considering the supply chain?

Yes, go for it! The Supply Chain world needs you! Look at University programs such as Michigan State, Penn State, Rutgers, University of Texas, Arizona State University are just a few of a huge laundry list that ISM has on their website. In addition, groups like CSCMP, Procurement Leaders, ISM, SIG and many others offer continuing education courses to enhance your knowledge of Supply Chain. And for those that like to read, there are many great books out there (I am happy to supply a few of my favorites).

Any advice for the industry itself?

Yes, embrace women in Supply Chain. Their abilities are superb and when you select the right one, she can bring your company greater value than ever imagined. But you must watch, listen, learn, coach and offer opportunities to excel. And lastly, be a mentor to those that have a spark, work hard and apply themselves to make a difference. Man or woman, the Supply Chain of the future depends upon the perfect mix of talent. And as we know, Supply Chain talent is experiencing a shortage.

Mickey North Rizza is VP, Strategic Services at BravoSolution, assisting clients to bring & deliver more impactful value in Procurement, Sourcing and Supplier Relationship Management. She developed the first Procurement alignment tool, called BravoAlign that has aided many clients on their supply management excellence journey.

Prior to joining BravoSolution, Mickey was a Research Director for the Procurement and Sourcing practice of the Supply Chain Team at Gartner and AMR Research. She was an award winning supply chain analyst during her 7 year tenure and is still a highly popular thought leader and speaker in Supply Management.

Prior to becoming an analyst Mickey was a practitioner for 22 years. Her practitioner career includes Moduslink Corporation, where she held the positions of Vice President of Global Supply Base Management and Director of Procurement and Sourcing. At Moduslink, she was responsible for implementing strategic sourcing programs, driving strategic positioning of procurement and materials in Europe and the Americas, and introducing new procurement technology.

Mickey also worked as a Materials Manager at M/A-Com, Inc. a division of Tyco International. While at M/A-Com, Mickey developed and implemented strategic procurement plans and integrated roadmaps to accompany a supply chain model. In addition, she introduced a pilot manufacturing resource management system.

During her career, Mickey also worked as a Purchasing Manager at Advanced Techcom, Inc., Innova Corporation and Motorola; and was also a buyer & sourcing agent at AM General, a division of LTV Missiles and Electronics and Grumman Olson.

Mickey is a member of the Institute for Supply ManagementTM. She is a founding member of the ISM Supply Chain Risk Management Group, which she chairs for 2015. She was voted Top Female Supply Chain Executive 2013. Mickey is an active nonprofit volunteer with her work at ISM, as a Delta Gamma Foundation Trustee and Secretary (2006-2009) and her past board work with Lowell’s Boat Shop in her home town of Amesbury, MA.

Mickey earned a B.A. in Materials Logistic Management from Michigan State University.

How to increase prices and retain customers

How to increase prices and retain customers