by Jennifer Hart Yim | Oct 22, 2019 | Blog, Current Events, Logistics, Manufacturing & Distribution, Strategy, Supply Chain

Amazon has changed the way we do business. Supply chain companies need to get on board with Amazon’s e-commerce strategy or risk losing business.

It is no secret that Amazon has dominated the online retail industry. Amazon Prime has shifted consumer expectations so that waiting 5-7 business days for your online order is no longer acceptable. With people now ordering anything from couches to groceries online, companies need to get on board with this shift to e-commerce or risk missing out on many sales.

Consumers now more than ever want access to more inventory no matter if they are shopping online or in stores. Many companies report the struggle of trying to keep up with this retail giant, and current-day supply chains have certainly felt the impact.

Historically, supply chains have been set up to support a network of stores using the multichannel business model. This includes retailers managing their different channels almost as separate businesses. These channels are what businesses use to get their goods and services to their consumers. For example, many retailers use brick-and-mortar stores as well as e-commerce when it comes to selling.

So, what’s the problem with this? Well, the customer’s experience can vary depending on the shopping channel they choose. Retailers often keep their online and brick-and-mortar inventory separate, which can lead to a frustrating shopping experience for the customer.

I am sure at some point in your life you have had the experience of walking into a store looking to return an online order only to find out it must be returned to the company through the mail. Customers do not view a brand in silos, and the same selection of inventory is expected whether they are shopping online or in a physical store. Companies also run the risk of losing a sale if the exact item the consumer wants is unavailable or sold out. This is one area that allows Amazon to shine because they maintain one pool of inventory that is not separated by different channels of business.

A 2016 UPS survey found that, for the first time, shoppers revealed they bought more of their purchases online than in stores. It’s hard to tell what is the main driver behind this shift, but you can’t help but think of Amazon. It’s hard to comprehend how other companies not only compete but just even keep up with the trillion-dollar company with a revenue of $10.07 billion in 2018.

This is where the omnichannel business model comes into play. Omnichannel combines physical and online commerce to create a more seamless shopping experience for the consumer. While this business model is not a result of Amazon, it certainly puts companies in a better position to compete. The goal here is to provide the same customer experience throughout each channel while ensuring the product reaches the customer as fast as possible.

Characteristics of an omnichannel business model include:

- Buy online pick up in stores

- Stores shipping to other stores

- Dropshipping

- Order fulfillment from store

Nordstrom finding ways to differentiate from the competition

Online shopping provides many benefits to consumers, but it does not come without its own challenges. It is fairly common to buy a shirt online only to find out it is the wrong size. It can be a hassle to mail the item back, and consumers often opt out of this and chalk the purchase up to a loss. Nordstrom understands this pain point and took it upon themselves to offer a solution by creating service hubs called Nordstrom Local. The sole purpose of Nordstrom Local is to make the online shopping experience effortless. While these hubs do not contain designated inventory, they provide a handful of services to the customers.

They offer:

- Pickups

- Returns

- Stylist

- Dressing rooms

- Tailoring services

- Same-day delivery (if ordered before 2 p.m.)

- Espresso drinks, juices, wine & beer

As a consumer, what more could you ask for? The idea is that you order a variety of clothes online and have them delivered to Nordstrom Local. Here you can try on your purchases in their dressing rooms. If it doesn’t fit, no problem — they’ll mail it back for you. Need it hemmed? There’s a tailor on-site.

Nordstrom has held its own in the retail space. With 2018 revenue reaching $15.5 billion, it is hard to argue with their success. They must continue to innovate and find new ways to connect consumers to their product. Trying out this concept in Los Angeles has proven to be successful, and they are looking at opening up hubs in New York next.

Kohl’s joins forces with Amazon

Kohl’s, like many retail stores, welcomes any opportunity to increase foot traffic. Over 1,000 of their stores are now accepting returns from Amazon. Again, we see a pain point of online shopping removed for the consumer. You can bring your unwanted Amazon item to Kohl’s, and they will pack, label, and ship the item at no cost. The hope is that Amazon customers will flock to Kohl’s and hopefully buy some of their inventory on the way.

Their revenue has continued to rise over the past four years and reached 20 billion in 2018. This is a bold idea that can set Kohl’s apart from the competition by delivering a service that is unique to them. Amazon needs a way to keep its customers happy and Kohl’s needs to increase foot traffic, so it appears to be a win-win for all parties involved — including the consumer.

While Kohl’s new idea offers fewer services than Nordstrom’s, they are opening themselves up to a wider consumer market, and with this will likely come more sales. They have addressed the expected increase in expenses that will come with having to hire more employees and spending more on logistics, but the expected payoff is potentially massive.

Comparing strategies

It’s hard to tell which strategy will prove to be more profitable. The only thing that is for certain is that the shift toward e-commerce is not slowing down anytime soon, so companies need to look at how they connect consumers to their product. If the goal is to get your product to the consumer, then your supply chain needs to be tailored to this objective.

Amazon may have the upper hand now, but you never know what new idea could pop up in a few years. In the meantime, companies are faced with the harsh reality of ever-growing competition. Consumers are now hopping on their computers or mobile devices to choose from a plethora of inventory.

Amazon is not completely to blame when it comes to the evolution of consumer expectations, but they have certainly impacted them. Companies wanting to compete are left to make tough but critical decisions on what their next move will be.

This article was written by Emily Standish, an MBA student at the Peter T. Paul College of Business and Economics at the University of New Hampshire, specializing in Finance and Information Systems & Business Analytics. She graduated from Merrimack College in 2017 with a B.S. in Business Administration and Management with a concentration in Finance and currently works as a Corporate Financial Analyst.

Related posts:

by Fronetics | Oct 15, 2019 | Blog, Content Marketing, Manufacturing & Distribution, Marketing, Supply Chain

The analog supply chain model is outmoded and inefficient. Here’s how digital transformation is reinventing manufacturing.

Highlights:

- Manufacturers are increasingly adopting artificial intelligence and machine learning technologies.

- The traditional analog supply chain model is unable to compete with digital disruptors in a volatile market.

- Digital transformation empowers manufacturers to create sought-after personalized experiences for buyers.

Digital transformation isn’t just the latest buzzword in supply chain circles. It’s an ongoing trend that’s revolutionizing manufacturing and supply chain efficiency. According to a recent report from Accenture, 78% of CFOs are spearheading initiatives to improve efficiency through adoption of digital technology.

Digital transformation empowers manufacturers to meet the evolving demands of a customer base with rising expectations for customer service. The digital technologies that are emerging today offer analytics that are vital for forecasting and understanding how to shift the balance of supply and demand.

3 ways that the analog supply chain model is outdated

Supply chain management expert Frank Meerkamp writes, “The traditional supply chain is a tapestry built on an outdated analog network – yet it exists in a digital world.” The difficult truth is that in today’s climate of rapidly shifting market demands and an increasingly interconnected world, manufacturers must embrace digital transformation or be left behind.

Before we look at how digital transformation can benefit manufacturers, let’s take a moment to examine the challenges presented by an outdated analog supply chain.

1) Market volatility

Today’s markets move at a breakneck pace. Thanks to a constantly shifting geopolitical landscape, changing regulations and sanctions, and the unpredictability of cost and supply, manufacturers face market volatility, uncertainty, and a high level of risk. The analog supply chain model leaves companies without the agility to respond and pivot quickly and to operate efficiently on a global or regional scale.

2) Competition from digital disruptors

Perhaps the most powerful example of the way in which digital disruptors are challenging legacy leaders is the Amazon effect. Amazon has effectively situated itself as an innovator and easily has outpaced rivals in multiple sectors. Companies that continue to embrace an analog supply chain model simply cannot compete with those that have fully embraced digital transformation.

3) Rising customer expectations

While it can be tempting for B2B companies to bury their heads in the sand, believing that digital marketing is purely a B2C necessity, the reality is that supply chain companies must embrace digital marketing as part of their digital transformation. Buyers expect hyper-personalized experiences, as well as customized products, and the kind of execution that’s impossible for manufactures to deliver within the analog supply chain framework.

4 ways digital transformation addresses today’s challenges for manufacturers

As the complexity of the supply chain increases, embracing digital transformation is the clearest path to success for manufacturers. While companies that cling to an outdated analogue model struggle with eroding margins and an inability to compete, those that establish “a data-driven supply chain,” writes Meerkamp, “can gain advantages in increased forecasting accuracy, identifying and resolving issues in real time, creating new segmentations, and delivering on consumer requirements with speed, specificity, and scale.”

In short, digital transformation uses data to drive visibility and agility for manufacturers, allowing them to operate efficiently and profitably.

1) Establishing visibility and centralized control

The AI and machine-learning technologies available today enable manufacturers to meet the challenges presented by an increasingly complex supply chain. Massive sets of data can be captured and processed, providing invaluable real-time visibility. Not only that, but manufacturers can leverage this visibility to centralize data and decision-making.

2) Creating new performance engines

Thanks to the ability of AI technologies to process enormous quantities of data, digital transformation enables “powerful resolution engines, based on real-time root-cause analyses, to automate the execution of supply chain functions, and optimize transactions to meet strategic objectives,” says Meerkamp. These technologies facilitate the forecasting and immediate decision-making necessary for manufacturers to operate efficiently.

3) Facilitating agility

Today’s marketplace moves faster than ever, and market forces are constantly shifting. Agility has never been more important for companies to compete. Intelligent technologies allow supply chain companies to establish a management model that is collaborative, data-driven, and platform-based. Digital transformation enables the sharing of qualitative information as well as real-time data and implications. This in turns enables agile management, ready to meet the shifting demands of the marketplace.

4) Developing personalization and flexibility

One of the biggest challenges manufacturers face today is the increasing buyer expectations of personalized experiences. AI technology enables the creation of segmentation strategies, addressing buyers’ personalized needs based on various factors, including channel, location, and service level. Real-time visibility into market data also leads to greater insight into buyers’ needs and how to meet them.

Organizations that embrace digital transformation are empowered to create personalized experiences for their customers and operate with the agility, visibility, and centralization necessary to compete in today’s marketplace.

Related posts:

by Fronetics | Jul 25, 2019 | Blog, Manufacturing & Distribution, Marketing, Marketing Automation, Robotics & Automation, Supply Chain

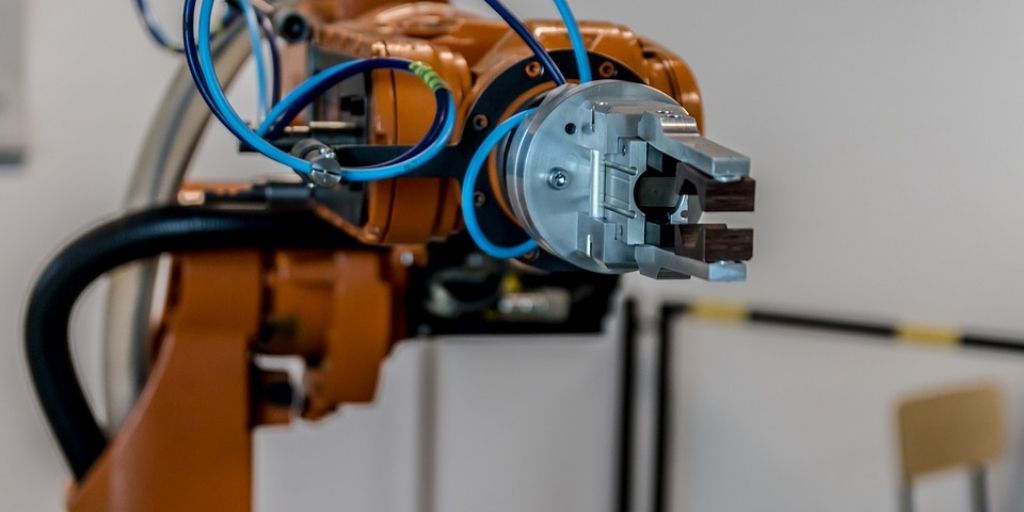

Implementing robotics and automation for manufacturing can be costly and a challenge for public perception – but, ultimately, these technologies are crucial assets for the industry.

Highlights:

- Hurdles companies face concerning automation include public perception, potential safety hazards, and cost.

- However, robots actually make factories safer and protect human workers from having to perform dangerous tasks.

- Advantages of automation include decreased long-term costs, reduced error rate, improved productivity, and enhanced data collection.

As machine learning, or Artificial Intelligence (AI), gains sophistication and technologies continue to improve, supply chain companies are increasingly needing to evaluate the benefits and pitfalls of robotics and automation for manufacturing.

While current evidence suggests that experts are correct in predicting that automation will prove a significant competitive advantage, manufacturing companies are often faced with equally significant hurdles when it comes to implementing these technologies.

So, on balance, are robotics and automation for manufacturing assets, or do they present insurmountable hurdles? Let’s look at the case for each.

3 challenges of robotics and automation for manufacturing

1) Perception

When companies begin considering or implementing robotics and automation for manufacturing, they do so in the context of a public steeped in the kind of sci-fi lore that breeds hysteria on this issue. While public fears of Cylons and the like taking manufacturing jobs may seem like frivolous concerns, the battle that companies face when it comes to public perception is quite significant and should not be overlooked.

In addition to the more hysterical fears of robot uprising, manufacturing companies are faced with the need to combat negative public perception and employee fears when it comes to replacing traditional manual labor with capitalized assets. In short, the fear that “robots are taking our jobs” should not be underestimated as a challenge faced by companies considering manufacturing automation.

2) Dangers

In addition to cultural perceptions of robots as potentially threatening, there are real safety concerns when it comes to robotics and automation for manufacturing. A notorious accident in a Volkswagen factory in Germany, in which a worker was killed by a malfunctioning robot, has been widely reported in the media and serves as a cautionary tale about the dangers posed by automation.

Manufacturers seeking to implement automation are faced with the task of ensuring that factories remain safe for humans and robots to work collaboratively. This requires investment in safety features, as well as training and oversight.

3) Implementation costs

Perhaps the biggest hurdle to companies’ acquisition of robotics and automation for manufacturing is the cost. While these technologies are becoming more affordable, the high initial capital outlay presents a serious barrier, particularly for smaller and midsized manufacturers.

In addition to the costs of equipment, there are expenses associated with maintenance, compliance, software, and human worker training. Companies may be aware of the long-term benefits of automation but unable mount the initial costs or stomach ongoing expenses.

Robotics and automation for manufacturing: the case for overcoming the hurdles

Now it’s time to look at how these technologies are assets and whether it’s worth facing the challenges associated with implementing them.

Robots aren’t here to replace humans.

When it comes to combatting the public perception that robots will render humans obsolete, there’s one simple truth that sums it up best: robots will not replace humans. In fact, automation works best alongside human workers and maximizes the strengths of each, leading to enhanced employee value. Automation frees up human workers to work in their core competencies, focusing on strategic work, oversight, and administration.

Automation helps make factories safer.

While the dramatic examples of robots causing injury and death are harrowing, and deserve attention, it’s important not to sweep under the rug the fact that automation actually makes factories much safer for human workers. By performing tasks that put humans at risk, robots can remove workers from traditionally hazardous situations or exposure to harmful materials.

As these technologies develop, they are becoming increasingly safe and include provisions that facilitate working collaboratively with humans. Robotics can increase access to difficult or dangerous locations. Improvements in sensors, dexterity, artificial intelligence, and trainability are helping to ensure that robotics and automation for manufacturing are safe.

Automation as a value driver

While costs associated with implementation and maintenance may be significant, arguably, with the competitive advantages presented by robotics and automation for manufacturing, companies can’t afford not to automate.

Robots improve the speed and accuracy of routine operations, reducing costly error rates and increasing productivity. They decrease long-term costs, provide labor utilization and stability (particularly when labor is in short supply), and optimize picking, sorting, and storing times. The vastly improved data collection provided by automated manufacturing means reducing the frequency of costly inventory checks while increasing accuracy.

The bottom line: the hurdles presented by robotics and automation for manufacturing are well worth navigating.

Related posts:

by Jennifer Hart Yim | Jun 26, 2019 | Blog, Content Marketing, Manufacturing & Distribution, Marketing, Supply Chain, Talent

The global Supply chain provides goods faster and more efficiently than ever before. Here are the top supply chain skills for one of the most important industries: manufacturing.

Highlights:

- Sitting at the intersection of raw materials acquisition and distribution of finished goods, manufacturing is one of the most crucial functions within the global Supply Chain.

- If you’re in Manufacturing purchasing, think closely about what sort of buying you’re doing, how to diversify that experience, and deepen your understanding of the market you’re buying in – there are big dividends for those who do.

- Boosting your skills with continuous improvement, just-in-time manufacturing, and Six Sigma are some of the best ways to distinguish yourself in the field.

This guest post comes to us from Argentus Supply Chain Recruiting, a boutique recruitment firm specializing in Supply Chain Management and Procurement.

The global Supply Chain provides goods to consumers faster and more efficiently than ever before, and there’s a staggering diversity of Supply Chain professionals making that happen. Today, we want to take a moment to highlight the skills profile for one of Supply Chain’s most important industries – which also happens to contain one of its hottest job markets: Manufacturing.

Sitting at the intersection of raw materials acquisition and distribution of finished goods, manufacturing is one of the most crucial functions within the global Supply Chain. Despite perennial political statements around the “demise of manufacturing,” the sector is quite strong in Canada, especially in the Supply Chain, Purchasing and Logistics functions.

At Argentus, we’ve always worked in manufacturing recruitment, but we’ve been making a big push into this area recently, including in the areas of Aerospace, Consumer Electronics, Automotive, Electrical Manufacturing, Manufacturing Automation, and Food Production. We’ve seen what’s happening in the industry firsthand: dynamic companies are redefining the space, using a strong Supply Chain to scale up quickly while controlling costs.

In the past few months, we’ve helped a Food Production company with an innovative approach to product development scale up their Procurement and Plant bench strength. We’ve bolstered a fast-growing Aerospace company looking for highly-technical technical buyers to boost their new product introductions. We’ve helped a startup manufacturer seeking their first Supply Chain Manager to implement a sourcing, distribution and logistics strategy for the first time.

And these are just a few. These experiences, combined with our intelligence in the marketplace, have given us a good understanding of the hottest skills in Manufacturing Supply Chain jobs in the market as of right now.

A couple caveats: this reflects manufacturing positions at the corporate Supply Chain Management level and not the shop floor / distribution centre level. It also isn’t exhaustive of all required skills, just those that we’ve noticed being in high demand recently.

So without further ado, here are some of the hottest skills:

“Direct” Purchasing: Raw Materials, Packaging, Food

Buying raw materials has always been a vital part of manufacturing – after all, what can you produce without raw materials? – but clients’ demand for specific raw materials purchasing experience is rising. Whether it’s food ingredients or building materials, companies are looking for individuals who can think strategically about raw materials to find better suppliers and processes. For certain raw materials, they want individuals who have a deep understanding of particular commodities markets. If you’re in Manufacturing purchasing, think closely about what sort of buying you’re doing, how to diversify that experience, and deepen your understanding of the market you’re buying in – there are big dividends for those who do.

ERP Skills:

It probably goes without saying at this point, but a high degree of competency with ERP systems is a must-have in today’s manufacturing Supply Chain. Many of the vital Supply Chain planning functions for most manufacturing processes (production planning, supply network planning, etc.) run through ERP systems like SAP, Oracle or Microsoft NAV, so it’s no wonder that most front line workers distinguish themselves with excellent command of these systems.

Buying “build to spec” for highly engineered components:

If you’re working in a highly technical subsection of manufacturing (electrical, aerospace, etc.), more companies are seeking Procurement people with the technical background to source components at a very early stage of new product development. We’ve worked on a number of searches recently where our client is looking for new product buyers who can source based on technical specs, as opposed to drawings. People with mechanical engineering backgrounds are excellent for these roles. But even if you don’t have that background, an understanding of detailed technical specifications can give your career a boost over more transactional buyers.

Continuous improvement:

Lean manufacturing, Kaizen and continuous improvement are decades old at this point, but manufacturers who fail to implement these models are still falling behind in the marketplace. The ability to constantly improve manufacturing processes is still one of the chief differentiators for Supply Chains, and companies are constantly on the lookout for people who can help transform and improve their operations. Boosting your skills with continuous improvement, just-in-time manufacturing, and Six Sigma are some of the best ways to distinguish yourself in the field.

So that’s some perspective from the front lines of Supply Chain recruitment in manufacturing. But what are you seeing in the marketplace, either as a Supply Chain professional or hiring manager?

Related posts:

by Fronetics | May 9, 2019 | Blog, Content Marketing, Logistics, Manufacturing & Distribution, Marketing, Supply Chain

Putting your audience’s informational needs first when publishing blog content is the only way to guarantee success in the modern marketing landscape.

Highlights:

- Audiences are increasingly ignoring promotional messaging.

- Buyers are seeking value from vendors outside the sales funnel.

- Information is your best asset — publish what you know.

The latest industry research from the Content Marketing Institute indicates that nearly all (90%) of the most successful B2B content marketers have one thing in common: they prioritize their audience’s informational needs over their sales/promotional message. And that’s compared with only 56% of the least successful B2B content marketers.

Materials-handling marketers should take note when making decisions about publishing blog content. We see companies in this sector making this mistake all the time. They want to fill their blogs with information about their products. But to achieve success in today’s B2B purchasing landscape, you need to be prioritizing your audience’s needs over promotional messaging.

Sales pitches get ignored

A large reason for shifting focus is because audiences are increasingly tuning out sales pitches. This generation of buyers has been heavily marketed to their entire lives, and they don’t hesitate to swipe left at the slightest hint of someone trying to sell them something.

[bctt tweet=”This generation of buyers has been heavily marketed to their entire lives, and they don’t hesitate to swipe left at the slightest hint of someone trying to sell them something. ” username=”Fronetics”]

Think for a moment about your own personal experiences with email, social media, and even phone calls. The truth is, most of us tune out overt sales pitches, either hitting delete or scrolling past them. We’ve moved beyond a time when marketing is about pushing your products.

Your blog, therefore, should not be another channel for selling. But, what kinds of information should you publish?

Provide value by putting customer needs first

The answer is actually quite simple. What information or expertise do your buyers want? Your most valuable commodity is your unique understanding of the challenges your audience faces. If you begin publishing blog content that answers their questions, they’ll be more likely to find you, remember you, and become your customer.

As you think about publishing blog content, take a step back and think about the questions your buyers ask, either of you, on social media, or elsewhere. Examine industry publications to determine the challenges faced by your target buyer persona.

Does your content answer those questions? Does it offer value in and of itself? And does it inform your audience about how you are there to help them? If the answer to these questions is yes, then you’re taking the right steps toward materials-handling marketing with today’s B2B buyers.

Related posts:

by Fronetics | May 8, 2019 | Blog, Content Marketing, Logistics, Manufacturing & Distribution, Marketing, Strategy, Supply Chain

Brand awareness is key in optimizing your content marketing efforts but can be challenging to quantify. Here are four metrics to help you measure brand awareness.

Highlights:

- Use tools, like SharedCount, to track the number of times a piece of your content has been shared across different social media platforms.

- Use the analytics from blog share bars to track the popularity of your posts and help shape content for your editorial calendar.

- Taking the time to measure brand awareness will ultimately help you in optimizing your digital marketing efforts.

Video transcript:

I’m Katie Russell and I’m a marketing strategist here at Fronetics. Today I’m going to talk to you about four ways to measure brand awareness for your packaging company.

Brand awareness is the extent to which customers – both potential and current – are able to recognize your brand. It is key in optimizing your digital marketing efforts, but it can be hard to quantify. Here are four metrics to help you start measuring brand awareness for your packaging company.

1. Social media reach

Social media reach is the total number of people that your content can reach across social media platforms. Use tools like SharedCount to track the number of times a piece of your content has been shared across different social media platforms, like Facebook, Instagram, and even LinkedIn. This can help you figure out what platforms perform best for your content and can also help you shape the kind of content that you’re putting on social media platforms.

2. Brand mentions

How people talk about your packaging company online? If they are, you need to know about it. Try tracking tools like Google Alerts or Hootsuite to make sure that you know every single time someone talks about your packaging brand or any of your products or services.

3. Blog shares

Here are Fronetics, we talk a lot about the importance of having a blog that posts valuable and informative content to your readers. What’s also important is giving your readers the ability to share this content. It’s as easy as adding a share tool to the side of your blog posts. This helps you reach a larger audience and gain views from people that normally wouldn’t see your content. You can also use the analytics from these share bars to track the popularity of your posts and help shape content for your editorial calendar.

4. Search volume

Use tools like Google Adwords or Moz to track searches for your brand, products, even your blog and social media posts. It can help in refining your keywords that you use throughout your content to know specifically what people are searching for when they’re searching for your packaging brand.

Taking the time to measure brand awareness will ultimately help you in optimizing your digital marketing efforts and will also help increase leads. IF you need more information or need help getting started measuring your brand awareness, visit us at fronetics.com.

Related posts: